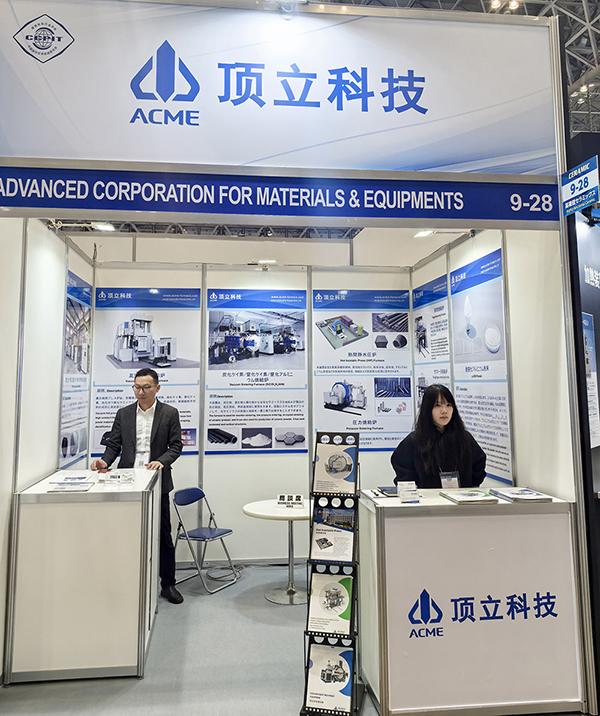

ACME Successfully Concludes Participation at Ceramics Japan 2025 in Tokyo

Event: Ceramics Japan 2025 - The International Exhibition for High-Performance Ceramics

Dates: November 12-14, 2025

Venue: Makuhari Messe, Chiba, Japan

Booth: Hall 2, Stand 9-28

ACME is proud to announce the successful conclusion of our exhibition at Ceramics Japan 2025 in Tokyo. We were delighted to showcase our advanced thermal processing solutions and materials at one of the industry's premier events.

Our booth in Hall 2 featured a focus on key technologies and materials central to the advanced ceramics industry, including:

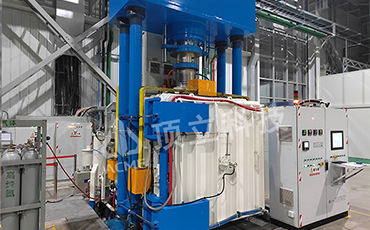

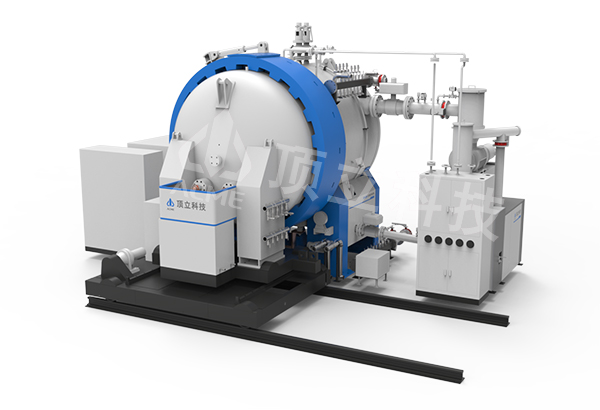

Hot Isostatic Press (HIP) Systems

Sintering Furnaces for SiC / Si3N4 / AlN

AlON (Aluminum Oxynitride) Powder

Ingot Annealing Furnaces / Sinking Annealing Furnaces

Aligning with the Exhibition Theme

The exhibition's theme revolved around innovation and advancement in high-performance ceramics. Our featured products are perfectly aligned with this vision, serving critical roles in the research, development, and mass production of next-generation ceramic components.

Industry Applications and Processed Products

The technologies and materials we presented are essential across a wide spectrum of high-tech industries:

Electronics & Semiconductors: Our sintering furnaces for Aluminum Nitride (AlN) and Silicon Nitride (Si3N4) are used to produce high-thermal-conductivity substrates, insulators, and components for semiconductor manufacturing. Ingot Annealing Furnaces play a key role in processing silicon and other material ingots.

Advanced Manufacturing & Automotive: Silicon Carbide (SiC) sintering solutions are vital for creating high-strength, wear-resistant parts, including seals, bearings, and cutting tools. Hot Isostatic Pressing (HIP) systems are used to densify materials and eliminate defects in critical automotive and aerospace components.

Optics & Defense: AlON Powder is the precursor for creating transparent ceramic armor and high-performance optical windows. Our specialized furnaces enable the sintering of these transparent polycrystalline ceramics.

Metallurgy & Materials Research: Our Vacuum Hot Press and Pressure Sintering Furnaces are utilized for developing and manufacturing composite materials, intermetallics, and other advanced materials requiring controlled atmospheres and simultaneous heat and pressure. Sinking Annealing Furnaces are used for stress relief and microstructural control in metal components.

A Sincere Thank You

We extend our deepest gratitude to all the visitors, clients, and industry partners who took the time to visit our booth. The engaging discussions, valuable insights, and shared passion for advancing ceramic technologies made the event a tremendous success.

We hope the connections made and solutions explored at Ceramics Japan 2025 will lead to fruitful collaborations. We look forward to seeing you again at future events!