ACME to Showcase Advanced High-Performance Ceramic Solutions at CERAMICS JAPAN 2025

ACME is proud to announce its participation in the prestigious CERAMICS JAPAN 2025, the leading international exhibition for high-performance ceramics. The event will be held from November 12th to 14th, 2025, at the Makuhari Messe, Chiba, Japan. We warmly invite you to visit us at Booth 9-28 in Hall 2 to discover our cutting-edge technologies and materials.

Exhibition Theme: Pioneering the Future of Advanced Ceramics

This year's exhibition focuses on innovation and sustainability in the ceramics industry. The theme, "Advanced Ceramics for a Sustainable and High-Tech Society," highlights the critical role of ceramics in driving progress across global industries. At ACME, we fully embody this spirit by presenting a comprehensive portfolio of sintering furnaces, powder materials, and thermal processing solutions designed for superior performance, energy efficiency, and reliability.

Our Featured Technologies and Materials

At our booth, we will feature a range of key products central to the manufacturing of high-performance ceramics:

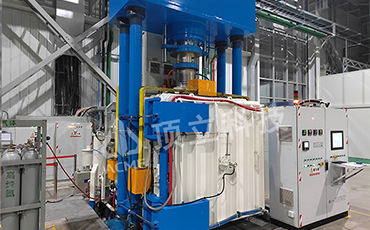

Vacuum Hot Press Furnaces: For producing fully dense, high-strength materials with fine-grained microstructures.

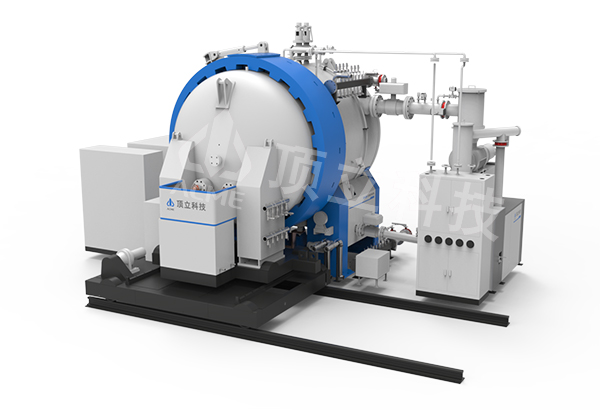

Hot Isostatic Press (HIP) Systems: Essential for eliminating porosity and enhancing the mechanical properties of critical components.

Pressure Sintering Furnaces: Enabling the creation of complex, near-net-shape parts with exceptional density.

Silicon Carbide (SiC) / Silicon Nitride (Si3N4) / Aluminum Nitride (AlN) Sintering Furnaces: Specialized high-temperature furnaces tailored for sintering these advanced technical ceramics.

Aluminum Oxynitride (AlON) Powder: A transparent ceramic material offering outstanding optical and mechanical properties.

Ingot Annealing Furnaces / Sinking Beam Annealing Furnaces: For stress relief and microstructural control in glass and metal components.

Application Industries and Processed Products

Our showcased technologies are pivotal in manufacturing components for a wide array of high-tech industries:

Electronics & Semiconductors: Our AlN sintering furnaces produce substrates and heat sinks, while our annealing furnaces are used for semiconductor wafer boats and diffusion furnace tubes.

Automotive & Aerospace: Components like turbocharger rotors (Si3N4), bearing balls, and cutting tools are sintered in our furnaces. HIP systems densify critical turbine blades and aerospace composites.

Energy & Power Generation: We supply furnaces for sintering seals, valves, and wear-resistant parts used in harsh environments. Ingot annealing furnaces are vital in the solar industry for silicon ingot processing.

Defense & Security: Aluminum Oxynitride (AlON) powder is used to create transparent armor and infrared windows for military vehicles and aircraft.

Industrial Manufacturing: Our Vacuum Hot Press and Pressure Sintering Furnaces are used to create robust dies, molds, and industrial wear parts.

Visit Us at CERAMICS JAPAN 2025

Join us at Booth 9-28 in Hall 2 to speak directly with our engineering experts, see detailed product demonstrations, and explore how ACME's solutions can enhance your manufacturing capabilities and drive your next innovation.

About ACME:

ACME is a global leader in providing advanced thermal processing solutions and high-purity materials for the ceramics industry. With a commitment to research and development, we empower our clients to push the boundaries of material science and engineering.