Aluminum Nitride Ceramic Vacuum Hot Press Furnace Process

In cutting-edge fields like 5G communications, power electronics and aerospace, material performance has become a key bottleneck for technological progress. When traditional ceramics fail to balance high-temperature resistance and thermal conductivity, aluminum nitride (AlN) ceramics stand out as an ideal choice for high-end device packaging and extreme-environment components, thanks to their superior comprehensive properties. The aluminum nitride ceramic vacuum hot-press furnace, the core equipment for manufacturing high-performance AlN ceramic products, bridges the gap between laboratory research and industrial application.

The AlN vacuum hot pressing process is a precise forming method driven by high temperature and pressure. Using high-purity AlN powder as raw material, the process is carried out in a sealed vacuum furnace. Under the combined action of high temperature and pressure, forming a dense AlN ceramic green body. This process avoids traditional binders, preventing impurities and ensuring optimal material performance.

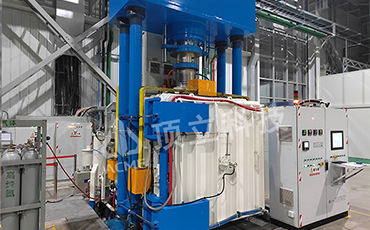

The vacuum hot press furnace is a complex system integrating multiple technologies, with its core components determining product quality. Its vacuum airtight system isolates oxygen to avoid AlN oxidation; the high-pressure structure ensures full particle bonding; the precise temperature control system meets different sintering requirements; and the anti-contamination design guarantees material purity.

High-performance AlN ceramics made by this furnace are widely used in power electronics, aerospace and semiconductor manufacturing. Looking ahead, the technology will develop towards higher efficiency, greener production, intelligence and cost reduction, further expanding its application scope.