CUSTOMER EXPERIENCE CENTER

Basic Functions: A R&D center for new equipment A;Pilotscale experiment platform for customer A; Teaching practice and training base.

Provide industrial heating equipment,C&SiC composite industrial heating equipment, vacuum heat treatment equipment, powder metallurgy industrial heating equipment,

cemented carbide equipment, Ceramic Sintering Equipment, 3D printing powder

ACME products include thermal equipment for carbon and ceramic-based composite materials, advanced heat treatment equipment, powder metallurgy thermal equipment, solid waste resource processing thermal equipment, metal 3D printing materials, etc. They are widely used in aerospace, new materials, new energy, automobiles, machinery, molds, medical, environmental protection and other industries.

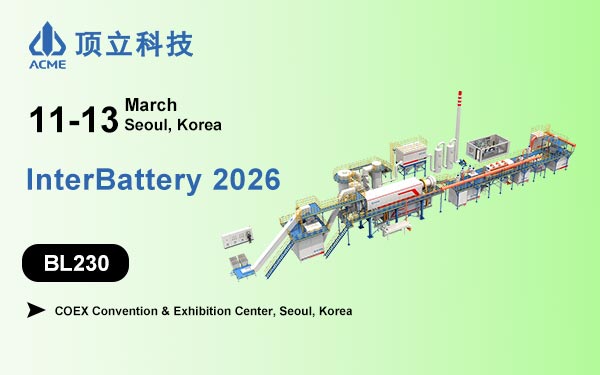

ACME cordially invites clients and partners to visit us at InterBattery 2026, Asia's leading battery exhibition.

MORE>>

The core equipment for transforming aluminum nitride powder into high-performance ceramic products—the aluminum nitride ceramic vacuum hot-press furnace—is now forging the “thermal conductivity backbone” for modern technology through precise process design. This advancement propels high-end materials from laboratory research toward industrial-scale applications.

MORE>>

In advanced manufacturing, new energy, aerospace, and other fields, silicon carbide ceramics have emerged as a key material to replace traditional metals and ordinary ceramics due to their exceptional properties of high strength, high-temperature resistance, and corrosion resistance. To transform the mixed green body of silicon carbide powder and binder into a structurally dense, stable-performance finished product, thesilicon carbide vacuum debinding sintering furnace plays the pivotal role of the “ultimate refiner.” By precisely controlling the entire debinding and sintering process, it removes impurities and strengthens the structure, fully unlocking the potential of silicon carbide ceramics. This provides robust and reliable material support for high-end equipment.

MORE>>

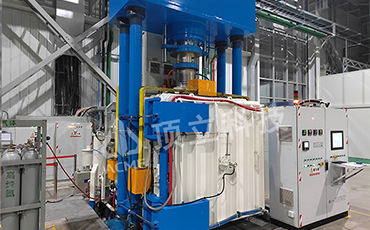

In today's era where high-end manufacturing pursues ultimate precision and performance, vacuum hot press technology is emerging as an “invisible hero” in core sectors like aerospace and electronic components through its unique solid-state bonding logic. This process, which abandons traditional fusion welding approaches, leverages the synergistic effects of vacuum environments and precise temperature-controlled pressure to achieve atomic-level bonding at the microscopic level. It provides a novel solution for connecting complex structural components and different materials.

MORE>>Founded in 2006, ACME (Advanced Corporation for Materials & Equipments) is located in Xingsha Industrial Park, with an area of 210,000 ㎡. ACME is a high-tech enterprise specialized in manufacture of industry heating equipment for new material and energy.Privacy policy | Terms and Conditions