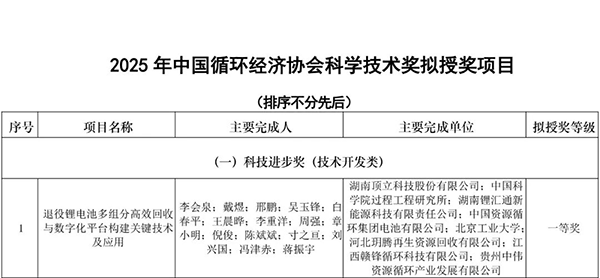

ACME Wins First Prize for Scientific and Technological Progress from the China Association of Circular Economy

Recently, the project “Key Technologies and Applications for Efficient Multi-Component Recycling of End-of-Life Lithium Batteries and Construction of a Digital Platform,” jointly completed by ACME and multiple institutions including the Institute of Process Engineering, Chinese Academy of Sciences, was awarded the First Prize for Scientific and Technological Progress by the China Association of Circular Economy.

With the rapid development of China's new energy vehicle industry, the volume of retired power batteries has experienced explosive growth. Statistics indicate that by 2024, domestic retired lithium batteries had reached 800,000 tons, with projections exceeding 3 million tons by 2030 and a recycling output value surpassing 100 billion yuan. Currently, the recycling industry faces significant challenges that severely hinder its healthy development, including an inadequate recycling network, difficulties in resource recovery of electrolyte, and low efficiency of integrated pyrolysis pretreatment equipment. Technological innovation is urgently needed to overcome these obstacles.

As a leading enterprise in the field of thermal engineering equipment, ACME has actively mobilized its scientific research capabilities to tackle technical challenges. The company has conducted systematic research focused on the efficient and green recycling of retired lithium batteries, achieving a series of innovative results.

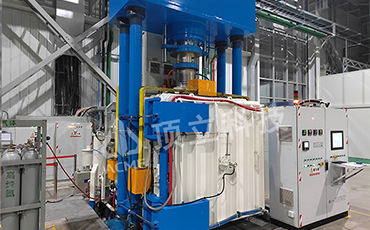

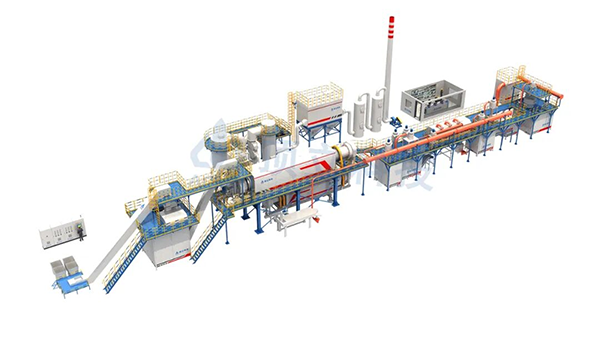

Disposal battery thermal pyrolysis recycling equipment

The project team established a digital intelligent management platform for retired lithium battery recycling and a comprehensive database spanning new energy vehicles, battery packs, and cells. This enables rapid, high-precision battery testing and precise matching of residual value utilization. They invented low-temperature evaporation technology for targeted recovery of electrolyte from discarded cells, along with specialized equipment, achieving refined recovery of solvent components for directed synthesis of high-quality products. Pioneered integrated technology and equipment for full-quantity, high-throughput pyrolysis with deep separation and pollutant control, enabling rapid discharge and crushing of discarded energy-containing cells, coupled with holistic pyrolysis and mineral phase regulation, precise separation of electrode powders/copper-aluminum materials, and comprehensive pollution control throughout the process. Established a complete technical system for efficient multi-component recycling and digital management ofretired lithium batteries.

The breakthrough and application of this technology have set a benchmark for the standardized and regulated development of China's end-of-life lithium battery recycling industry, holding significant importance for elevating the sector's overall capabilities.ACME’sTechnology will continue to deepen research into complete sets of equipment for end-of-life lithium battery recycling and processing, further enhancing equipment performance, reducing costs, and improving efficiency to support the green recycling of strategic metal resources for the global new energy industry.