Vacuum Aluminum Brazing Furnaces: Technical Analysis and Application Overview

I. Historical Background of Aluminum Brazing

1.1, Early Developments

Aluminum brazing technology began in the early 20th century and was initially used for simple metal joining. Early processes relied on chemical brazing fluxes (e.g., chlorides) to remove aluminum oxide films, but residual brazing fluxes tended to cause corrosion, limiting application scenarios.

1.2, vacuum brazing breakthrough

In the 1960s, with the aerospace industry's surge in demand for lightweight, vacuum aluminum brazing technology came into being.In the 1970s, the U.S. took the lead in developing a brazing flux-free vacuum brazing process, solving the corrosion problem of the traditional method, and promoting its application in high-end manufacturing.

Second, the application areas

Aerospace

Heat exchangers: aircraft engine oil cooler, evaporators for environmental control systems.

Structural components: satellite fuel storage tanks, rocket propellant pipelines, using brazing to realize thin-walled complex structure sealing connection.

New Energy Vehicles

Battery Cooling Plate: multi-channel aluminum liquid cooling plate, brazing to ensure high thermal conductivity and vibration resistance.

Motor casing: integrated brazing of lightweight aluminum alloy casing.

Electronics & Energy

IGBT thermal substrate: vacuum brazing of copper-aluminum composite heat sinks to reduce contact thermal resistance.

Solar Collectors: Corrosion-resistant runner welding of all-aluminum vacuum tube collectors.

Third, the process principle depth analysis

3.1, oxide film breaking mechanism

In a vacuum environment (10⁻³ to 10⁻⁴ Pa), aluminum oxide (Al₂O₃) undergoes thermal decomposition at temperatures above 580°C:

4Al + 3O₂→ 2Al₂O₃(standard generation of free energy ΔG ∘ = -1582kJ/mol)

The high temperature and low oxygen partial pressure promote the decomposition of Al₂O₃ into Al and O₂, the liquid filler metal (e.g., Al-Si-Mg alloy) fills the gap by capillary action.

3.2, interfacial metallurgical reaction

Thetypical brazing material AlSi7 (melting point 577-615 ℃) and the base material eutectic reaction, the formation of Al-Si-Fe intermetallic compound layer, the joint strength of the base material can reach more than 80%.

IV. Key Technical Pointsin theProcess Flow

Pre-treatment Process

Degreasing: Alkaline solution (pH 10-12,60℃) ultrasonic cleaning to remove rolling oil.

Acid washing: 10% HNO3+ 2% HF mixture treatment, remove oxide film and activate the surface.

Assembly precision control

Gap design: 0.05-0.2mm. A gap that is too large results in insufficient capillary force, while one that is too small hinders the flow of the filler metal.

Workholding fixture: made of Inconel 600 to ensure dimensional stability at high temperatures.

Thermal cycle curve optimization

Stepped temperature rise: a slow ramp rate of 5°C/min up to 300°C to prevent deformation.

Precise temperature control: ±3℃ PID algorithm to avoid overheating (>620℃) resulting in coarsening of the base material grain.

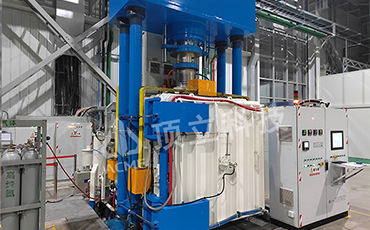

V. Vacuum aluminum brazing furnace system details

Core subsystems

Vacuum system: Roots pump (103 Pa level) tandem molecular pump (10-3Pa level), within 20 minutes to achieve a working vacuum of 5 × 10-3Pa.

Zoned heating design: 12-zone independent temperature control MoSi2heaters, with infrared thermography to achieve ±2℃ uniformity.

Advanced cooling technology

Graduated quenching cooling: first pass into the high-purity nitrogen (99.999%) forced convection cooling, 200 ℃ below the start of the water cooling coil.

Cooling rate control: 50-100℃/min adjustable to adapt to different alloy phase change requirements.

Intelligent monitoring system

Embedded PLC+HMI interface, real-time recording of temperature-vacuum-time curve (T-V-T chart).

Leakage rate monitoring: Helium mass spectrometer leak detector on-line detection, to ensure the sealing of the furnace body ≤ 1×10-⁹ Pa-m³/s.

Vacuum aluminum brazing technology is developing in the direction of intelligence, greenness and high precision. With the popularization of aluminum-based composites (e.g., Al-SiC), the new generation of brazing equipment will integrate in-situ inspection (e.g., real-time X-ray imaging) and adaptive control systems, promoting technological innovation in high-end manufacturing.