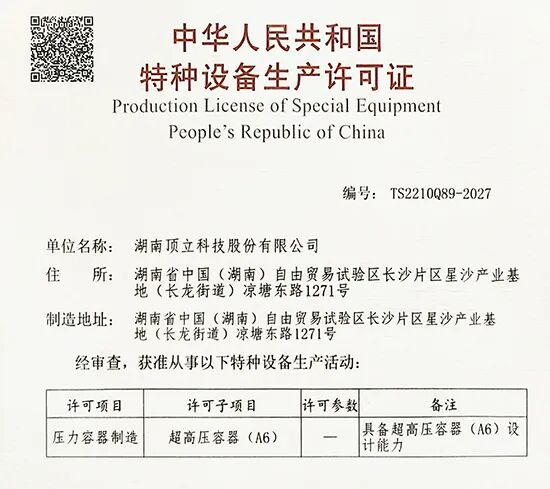

ACME has obtained the manufacturing license for ultra-high-pressure vessels (A6).

In December 2025, ACME successfully obtained the manufacturing license for ultra-high-pressure vessels (A6) and acquired the design qualification for such vessels, marking a crucial step forward for the company in the high-end equipment manufacturing field.

Ultra-high-pressure vessels refer to special equipment containers designed for pressures ≥100MPa, falling under the extreme high-pressure category of pressure vessels. Operating under exceptionally demanding conditions, they not only endure ultra-high pressures but also frequently face complex operational factors such as alternating loads, impulse loads, high temperatures, and medium’s corrosion. The (A6) production license represents the highest-level qualification in the fixed pressure vessel manufacturing field, signifying the pinnacle of manufacturing excellence within the industry.

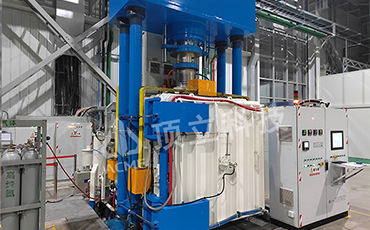

ACME has been deeply engaged in the field of specialized thermal processing equipment for nearly 20 years. Its products are widely used in the preparation of metals, ceramics, graphite, quartz, composite materials, and components, serving high-end manufacturing sectors such as aerospace, new energy, and third-generation semiconductors. The company possesses unique strengths in manufacturing ultra-high-temperature and super-large-scale equipment, with developed thermal processing systems capable of reaching temperatures up to 3300°C. Its chemical vapor deposition (CVD) and graphitization equipment feature effective heating dimensions of 3m × 3m × 6m and a volume of 54m³. The largevertical bottom-loading vacuum quenching furnacedeveloped by ACME has an effective heating zone of Φ2m × 6m, meeting the specialized requirements for processing large components in the aerospace area.

The successful acquisition of the Ultra-High Pressure Vessel (A6) Manufacturing License signifies that the company has attained the professional capability to manufacture ultra-high pressure equipment. This achievement represents another comprehensive upgrade and breakthrough in the company’s core competencies, encompassing technological strength, production standards, and quality control. Securing this qualification will provide robust support for the company's innovative development in the high-end equipment manufacturing sector.