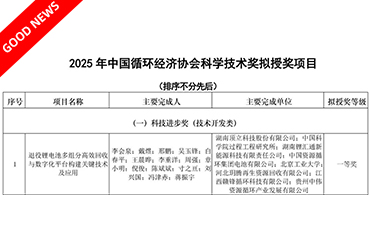

Vacuum high temperature graphitization furnace technology

Graphitization is a key heat treatment process. It refers to the heat treatment of materials mainly composed of carbon elements (such as petroleum coke, needle coke, bituminous coke, etc.) at ultra-high temperatures, so that the originally chaotic “chaotic layer” of carbon atomic structure is transformed into a regular, orderly three-dimensional graphite crystal structure.

It can be understood as a “high-temperature forging and purification” of carbon materials. After this process, the material's electrical conductivity, thermal conductivity, heat resistance, mechanical strength and chemical stability will beimproved qualitatively,making it a true “artificial graphite” material.

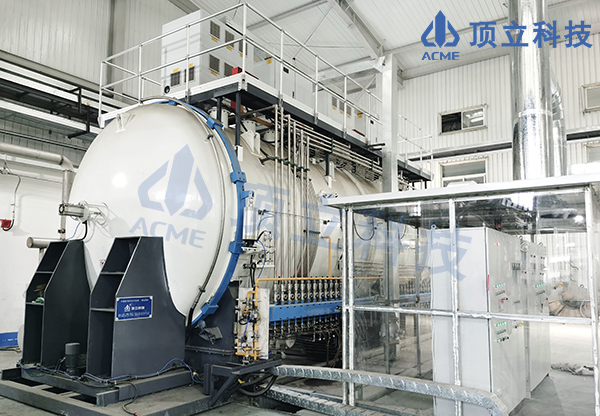

Vacuum high-temperature graphitization furnaceis a thermal equipment specially designed for realizing graphitization process, and its core features are as follows:

1, extremely high processing temperature: its working temperature is much higher than that of ordinary industrial furnaces, and the highest temperature usually reaches more than 3,000℃, which can provide the necessary energy for the rearrangement of carbon atoms.

2, high vacuum environment: the interior of the furnace chamber is pumped into a vacuum, which is one of the core features of the equipment. The vacuum environment can effectively prevent the material from reacting with oxygen, nitrogen, etc. at high temperatures, avoiding oxidized and abraded products, and at the same time helping the volatilization and removal of impurity elements, greatly enhancing the purity and quality of the products.

3、Accurate temperature control: Equipped with advanced temperature measurement and control system, it can accurately execute complex heating up, holding and cooling down curves to ensure the repeatability of the process and the consistency of the products.

4、Specific heating method: Usually adopts resistance heating system based on graphite materials (such as graphite heaters, graphite heat insulation screen), which utilizes graphite's own good conductive and heat-resistant properties at high temperatures to generate a uniform heat field.

Products treated with vacuum high temperature graphitization are the cornerstone of many high-end industries, and the main applications include:

-Lithium-ion battery anode materials: this is the largest application field at present. Natural graphite or artificial carbon precursors must be graphitized to become anode materials with excellent performance, which directly affects the energy density, cycle life and fast charging performance of the battery.

-Carbon fiber and composite materials: carbon fiber needs to be graphitized after carbonization in order to obtain higher modulus and superior mechanical properties, which is used in aerospace, high-end sports equipment and other fields.

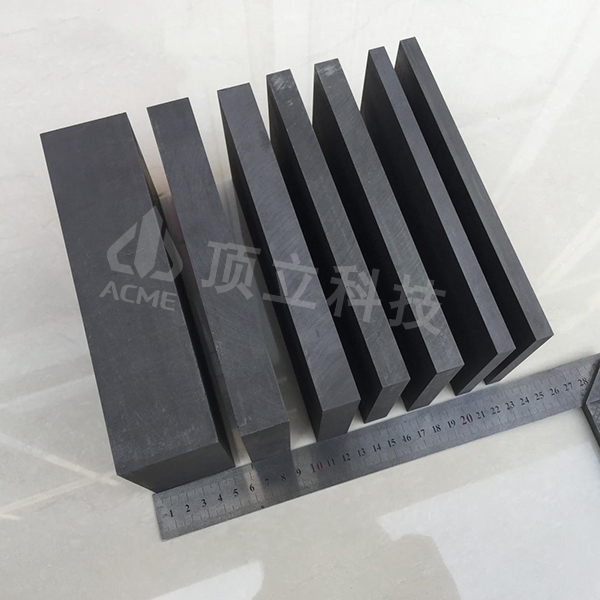

-Isostatic graphite: production of high purity, high density, isotropic special graphite, used in the semiconductor industry for single crystal furnace hot field, photovoltaic industry ingot casting furnace, EDM electrodes and so on.

-Special engineering materials: such as high-purity graphite crucibles, sintering molds, nuclear graphite, etc., which can not be separated from the key process of graphitization.

As a leading enterprise in the field of thermal equipment in China, the vacuum high-temperature graphitization furnace produced by ACME well reflects the above technical characteristics.

ACME's equipment is designed for high performance and reliability. The furnace body usually adopts a double-layer water-cooled structure to ensure that the equipment shell is still at a safe temperature during the internal ultra-high-temperature operation. In the design of the heating zone, advanced thermal field simulation technology is used to optimize the layout of the heat generator and heat shield, and to achieve excellent temperature uniformity within the effective zone of the furnace chamber, which is the key to ensuring the consistency of batch product quality.

In terms of control system,ACME's equipment integrates a highly automated system. Operators can easily set and store complex process curves, and the system is capable of precisely controlling core parameters such as temperature increase rate, vacuum level, pressure (if inert gas is passed through), and recording complete process data, meeting the high standards of traceability and repeatability required for modern industrial production.