Silicon Carbide Vacuum Sintering Furnace Technology

Silicon Carbide (SiC), as the name suggests, is a semiconductor material composed of the elements carbon and silicon. Usually, most of the semiconductor chips seen in the market are basically made of silicon as the main raw material. Silicon carbide (SiC) can be used as a semiconductor material, mainly because of its resistance to high temperature, high frequency and high pressure.

Extremely high hardness and wear resistance: its Mohs hardness is as high as 9.5, second only to diamond. This makes it an ideal material for the manufacture of wear-resistant parts, cutting tools and ballistic armor.

Excellent thermal stability: Silicon carbide does not soften or melt at high temperatures (decomposition temperatures of up to 2700°C or more at atmospheric pressure), and can maintain its mechanical strength and shape for long periods of time in environments of 1600°C or more.

Outstanding Thermal Conductivity: Its thermal conductivity range of 120-490W/(m-K) is much higher than most metals and ceramic materials, which means that it transfers heat extremely quickly, making it an excellent choice for the manufacture of radiators and high-temperature heat exchangers.

Wide-band semiconductor properties: SiC has aband gap of3.2 eV, which is the fundamental reason why silicon carbide is the “third generation semiconductor” material. Compared to conventional silicon semiconductors, its “bandwidth” ismuchwider.

Good chemical inertness: With 88% covalent bonding, the standard free energy of generation (-65.3 kJ/mol) is significantly lower than that of metal oxides, resulting in excellent chemical stability. In corrosive media such as sulfur-containing lubricants, only 2-3 nm amorphous SiO₂ passivation layer is generated on its surface, effectively blocking the intrusion of corrosive media.

I. Preparation of Silicon Carbide Products and the Central Role of Sintering

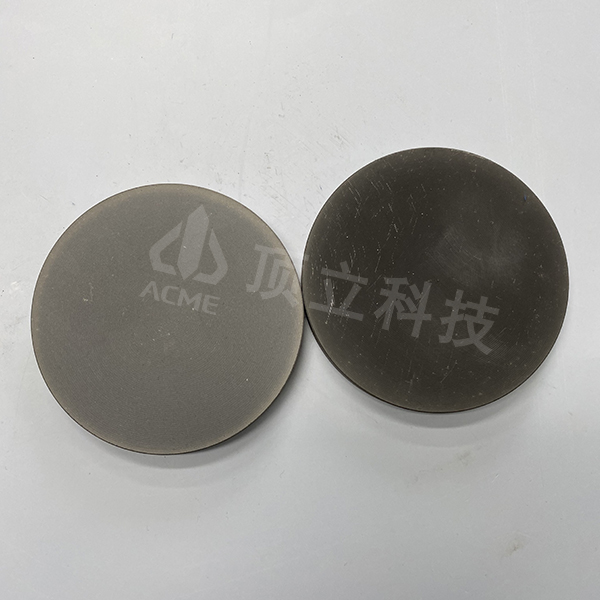

Totransform silicon carbide powder into dense components of practical value (e.g., semiconductor wafer trays, roll rods, nozzles, ballistic ceramics, etc.), it must undergo a crucial process - sintering.

Sintering is the process of forming a metallurgical bond between powder particles through material migration at high temperatures to obtain ahigh-density, high-strength product. Due to the strong covalent bonding properties of silicon carbide, its atomic diffusion rate is extremely low, and it usually requires extremely high temperatures (over 2000°C) to achieve densification.

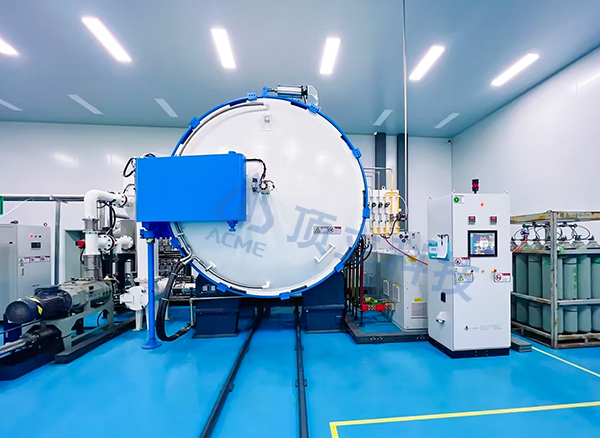

The vacuum sintering furnace plays an irreplaceable role in this process. It provides an extremely clean, oxygen-free and highly controlled temperature environment, which is essential for the preparation of high-performance, contamination-free silicon carbide ceramics.

Second, the characteristics and technical requirements of the vacuum sintering furnace of silicon carbide

Vacuum sintering furnace of silicon carbide is not an ordinary high-temperature furnace, which is the integrated embodiment of a number of technologies. Its core features and technical difficulties include:

1, very high maximum operating temperature: must be able to stably reach and maintain the ultra-high temperature environment required for the sintering of silicon carbide.

2、Advanced heating system and thermal insulation design: graphiteheating elements and high-performance carbon felt/hard felt insulation screen are usually used to ensure temperature uniformity in the furnace and to realize efficient temperature control.

3, excellent vacuum system: the need to configure high-performance vacuum pumping unit, can maintain a stable high vacuum throughout the process, effectively eliminating impurity gases in the furnace, to prevent the product from being oxidized at high temperatures.

4, accurate temperature control: need to be equipped with precision multi-zone temperature control system and reliable temperature measurement devices (such as infrared temperature measurement or tungsten rhenium thermocouples), to ensure that the product is heated uniformly, good process repeatability.

5, material compatibility: all materials in contact with high temperature and vacuum in the furnace must be able to withstand high temperatures, and their own volatiles are very small, to avoid contamination of the sintered silicon carbide products.

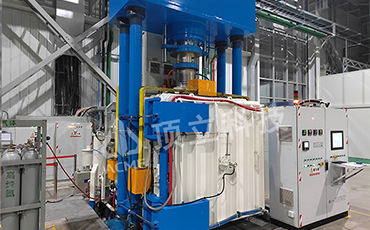

In the field of domestic thermal equipment,ACMEis one of the well-known suppliers. The developedsilicon carbide vacuum sintering furnaceis a specialized equipment designed for the characteristics of silicon carbide ceramic materials.

This type of equipment usually embodies the above mentioned technical features, and its design focuses on:

Furnace structure: adopting the mature double-layer water-cooled structure to ensure the safety of the equipment operation and the low temperature of the shell.

Temperature field uniformity: through the careful design and layout of the heat generator and insulation layer, it is committed to realizing a very small temperature difference within the effective temperature uniformity zone, which is the key to ensure the consistency of batch product performance.

Control System: The integrated automated control scheme is capable of programming and accurately controlling key process parameters such as temperature, vacuum, pressure, etc., and recording the whole process data for easy process traceability and optimization.

Safety and Stability: The design includes multiple safety interlock protections, such as over-temperature, water cut-off, over-current, etc., aiming to guarantee that the equipment can run stably and reliably for a long time and meet the needs of industrialized production.

Silicon carbide vacuum sintering furnace is the core equipment for the preparation of high-performance silicon carbide ceramics, and its technical threshold focuses on the synergistic control of “ultra-high temperature”, “high vacuum” and “high cleanliness”. The performance of such equipment directly determines the quality and reliability of the final silicon carbide products.