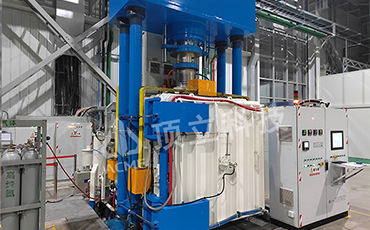

Vacuum water quenching furnace technology analysis

In the field of heat treatment of metal materials, quenching process is the key link to determine the material properties. The vacuum water quenching furnace, by virtue of its unique design that integrates vacuum technology with water quenching, not only avoids the drawbacks of traditional water quenching but also overcomes the efficiency limitations of oil and gas quenching. It has thus become an indispensable 'performance forger' in modern precision manufacturing. The following is an analysis of the technical principle, core advantages and practical applications.

I. Technical principle: the delicate balance of vacuum and quenching

The core logic of the vacuum water quenching furnace lies in the synergistic effect of “oxygen-free heating + controlled water cooling”, and its process chain is divided into three steps:

1. Vacuum environment heating

- In the high vacuum environment of 10-3Pa level, the workpiece is uniformly heated to the target temperature (e.g. 1220℃ for HSS).

- The vacuum state completely eliminates the risk of oxidation and decarburization, and at the same time promotes the desorption of internal impurities (such as hydrogen and oxygen) to enhance the densification of the material. For example, the hydrogen content of a titanium alloy workpiece was reduced from 150 ppm to less than 20 ppm after vacuum heating, thus avoiding the potential risk of hydrogen embrittlement.

2. Technical principle: the delicate balance of vacuum and quenching

The core logic of the vacuum water quenching furnace lies in the synergistic effect of “oxygen-free heating + controlled water cooling”, and its process chain is divided into three steps:

1. Vacuum environment heating

- In the high vacuum environment of 10-3Pa level, the workpiece is uniformly heated to the target temperature (e.g. 1220℃ for HSS).

- The vacuum state completely eliminates the risk of oxidation and decarburization, and at the same time promotes the desorption of internal impurities (such as hydrogen and oxygen) to enhance the densification of the material. For example, the hydrogen content of a titanium alloy workpiece was reduced from 150 ppm to less than 20 ppm after vacuum heating, thus avoiding the potential risk of hydrogen embrittlement.

II. Technological Advantage: Double Breakthroughs in Precision and Efficiency

1. Revolution in Material Suitability

- Traditional water quenching is only used for ordinary carbon steel due to oxidation, while vacuum water quenching makes stainless steel (such as 440C), high-temperature alloys (such as GH4169) and even titanium alloys (such as TC4) realize water-cooled strengthening. A medical device company uses this process to treat 316L stainless steel bone nails, the surface finish maintains Ra 0.4μm, and the hardness gradient fluctuation is ≤±1.5HRC.

2. Leap in deformation control capability

- Through the staged cooling strategy (such as water cooling to 500 ℃ first and then switch to air cooling), the deformation of complex workpieces can be compressed to 1/5 of the traditional process. For example, when processing modulus 12 20CrMnTi carburized gears, one gear manufacturer reduced tooth profile error from 0.15 mm (with oil quenching) to 0.03 mm (with vacuum water quenching).

3. Green Production Transformation

- The water quenching medium is non-toxic and recyclable, reducing VOCs emissions by more than 90% compared with oil quenching. A tool factory processing 500 tons of high-speed steel cutting tools annually previously consumed 200 tons of quenching oil. After switching to vacuum water quenching, its operating costs were reduced by 40%, and oil mist purification devices were no longer required.

Application examples: validation of effectiveness in multiple fields

1. Aerospace fasteners

- The tensile strength of TC4 titanium alloy bolts was increased from 900MPa to 1150MPa after vacuum water quenching, while maintaining an elongation of 8%, which meets the ASTM F468 standard for Class C fasteners.

2. Precision tool manufacturing

- M42 high-speed steel milling cutter adopts two-stage water cooling (first 100℃/s rapid cooling to 400℃, then 50℃/s slow cooling), the hardness reaches 67HRC at the same time, the edge chipping rate is reduced by 70% compared with oil quenching.

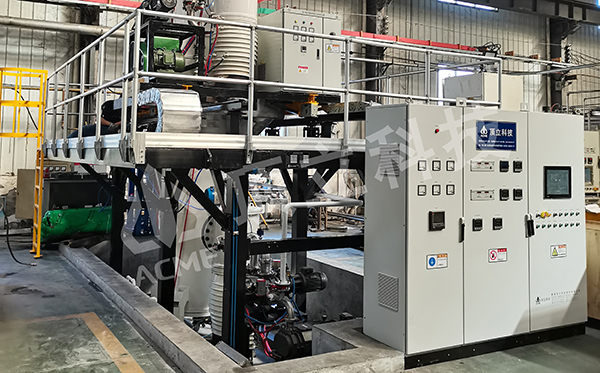

3. New energy parts processing

- Vacuum water quenching enables the production of fuel cell metal bipolar plates (material: 310S stainless steel) with a thickness of 0.1 mm and a flatness of ≤ 0.02 mm. This process also increases conductivity by 15% and eliminates the need for subsequent straightening.

The vacuum water quenching furnace technology solves the triple contradiction of oxidation, deformation and pollution in the traditional quenching process through precise control, providing an industrialized solution for upgrading the performance of high value-added metal products.