Silicon Carbide Chemical Vapor Deposition (SiC-CVD) Technology

Silicon carbide coatingis not a simple coating common in our daily life. It is a high-temperature chemical reaction that grows a dense, pure film of silicon carbide crystals on the surface of a substrate. You can think of this as a “crystal epitaxial growth” process rather than a simple physical coating. The film is microscopically highly organized and has the same excellent properties as bulk silicon carbide crystals. It inherits all of the excellent properties of silicon carbide and offers revolutionary surface enhancements for a wide range of substrates.

I. Characteristics of Silicon Carbide Coating

Silicon carbide coating prepared by CVD process has a series of excellent characteristics:

1. Extreme high temperature resistance: it can maintain very high strength and stability in high temperature environment, with excellent oxidation resistance, and the working temperature is much higher than most metals and alloys.

2. Excellent corrosion resistance: most of the strong acids, alkalis and molten salts have excellent resistance, can work stably in extremely harsh chemical environments.

3. Extremely high hardness and wear resistance: its hardness is close to diamond, low coefficient of friction, is the ideal choice for the preparation of wear-resistant parts.

4. Excellent thermal conductivity: at the same time with good electrical insulation (depending on the crystal structure), this combination of characteristics in the field of thermal management is extremely valuable.

5. High purity and densification: the CVD process can produce extremely pure, non-porous, defect-free coatings that effectively block the penetration and diffusion of impurities.

II. Application of Silicon Carbide Coating

Based on the above characteristics, SiC-CVD coating technology plays an irreplaceable role in a number of high-precision fields:

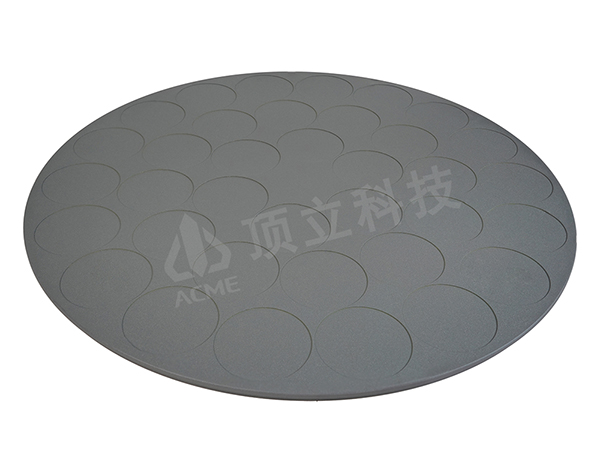

-Semiconductor wafer manufacturing: Used in the manufacture of silicon-based epitaxial wafers and silicon carbide epitaxial wafers, such as pedestals, trays and other consumables. The coating protects graphite parts from process corrosion, prevents metal contamination and greatly extends service life.

-Aerospace: Used in engine hot end components, leading edges of hypersonic vehicles and thermal protection systems to provide high temperature and ablative protection.

-Nuclear industry: as the cladding layer of nuclear fuel pellets, it can effectively prevent the leakage of fission products, and is a key material to ensure the safety of reactors.

III PREPARATION PROCESS OF SILICON CARBIDE COATINGS

Chemical vapor deposition of silicon carbideis the core process for the preparation of such coatings. The basic principle is that silicon and carbon-containing precursor gases, such as silane and propane, are passed through a precision high-temperature vacuum furnace chamber. These gases decompose and react chemically at high temperatures to produce silicon carbide molecules, which are then deposited and crystallized atom by atom on the heated substrate surface in an orderly manner, like building blocks, to form a homogeneous silicon carbide coating.

The entire process is extremely demanding on the equipment, requiring precise control of dozens of process parameters, the most critical of which are:

-Homogeneity and stability of the temperature field: determines the uniformity of the coating thickness and crystallization quality.

-Uniform distribution of the gas flow field: to ensure that the reaction gas reacts uniformly on each piece of workpiece surface to avoid uneven deposition.

-Precise pressure control: affects the gas transfer process and reaction kinetics.

-Sealing and cleanliness of the system: any trace of leakage or contamination can lead to coating defects or even failure.

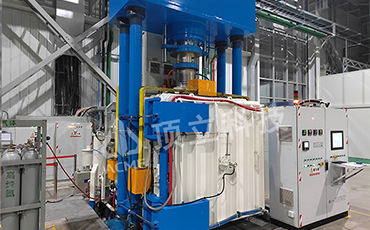

As a leading company of thermal equipment in China, the chemical vapor deposition (CVD) furnace for silicon carbide produced byACMEis the perfect carrier for the above difficult process. The equipment fully reflects the deep understanding of the CVD process.

The chemical vapor deposition furnaces ofACMEusually have the following outstanding features:

1. Precise thermal field design: the structure of heater and heat-insulating screen optimized by special design and simulation is adopted, which is able to create an extremely uniform and stable high-temperature zone in the huge furnace chamber.

2、Advanced Gas Delivery System: Equipped with precise mass flow controller and multiple gas inlets to ensure that the reaction gas and carrier gas can be accurately and stably fed into the furnace according to the preset ratio.

3、Integrated pressure control: integrated high-precision vacuum system and pressure control system can realize fast and smooth switching and stable maintenance from low vacuum to process pressure, providing an ideal environment for deposition reaction.

4, a high degree of automation and intelligence: the use of advanced PLC or computer control system, the operator can edit and store complex processes, to achieve the entire automated operation from the vacuum, temperature, deposition, cooling to pick up the material.

5、Excellent safety and reliability: In view of the process gases used (such as silane) are usually flammable and explosive or toxic properties, the equipment will be equipped with multiple safety interlocks, leak detection and emergency treatment system to ensure the safety of equipment and personnel.