Vacuum Graphitization Furnace Process for Carbon-Carbon Composites: Forging the “Graphite Core” of High-End Materials

In cutting-edge fields such as aerospace, high-end equipment, and new energy, carbon-carbon composites have emerged as critical materials for overcoming technological bottlenecks due to their unique advantages of lightweight, high strength, and high-temperature resistance. To achieve a qualitative leap in the performance of carbon-carbon composites—transforming them from“carbon-based blanks”into high-end products with both excellent thermal conductivity and stability—thevacuum graphitization furnacefor carbon-carbon composites plays the pivotal role of the“ultimate forger.”Throughprecise temperature control and process regulation in a vacuum environment, it drives profound transformations within the material's internal structure, fullyreleasing the potential of carbon-carbon composites to provide robust and reliable material support for high-end equipment.

I. Vacuum Graphitization Process for Carbon-Carbon Composites: The Transformation from“CarbonBase”to“Graphitized Masterpiece”

If the shaping and densification of carbon-carbon composite preforms represent“forming”and“filling,”then the vacuum graphitization process is the critical step that endows them with their“core performance.”Within theairtight vacuum furnace chamber, the material undergoes a gradual heating process. Under high temperatures, the disordered carbon structure within the carbon-basedgreen body transforms into ordered graphite crystals while expelling impurities and residual gases. This process requires no external intervention, thereby preventing oxidation contamination and promoting a more uniform internal structure. The result is a carbon-carbon composite material with superior thermal conductivity, stable mechanical properties, and enhanced high-temperature resistance.

Core Process Advantages:

Pure and Contamination-Free: The vacuum environment isolates oxygen and external impurities, preventing high-temperature oxidation of the material. It also rapidly expels volatiles generated during processing, ensuring product purity.

Enhanced Structural Order: Graphitization-driven transformation at elevated temperatures promotes more ordered carbon atom arrangement, significantly boosting thermal conductivity and structural stability;

Superior Performance: Post-graphitization, the material exhibits concurrent improvements in high-temperature resistance, corrosion resistance, and mechanical strength, making it suitable for extreme operating conditions;

Excellent Dimensional Stability: The design featuring gradual heating and uniform temperature maintenance effectively releases internal material stresses, preventing deformation and cracking while ensuring dimensional accuracy.

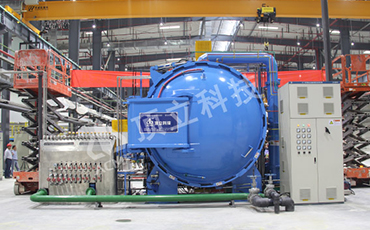

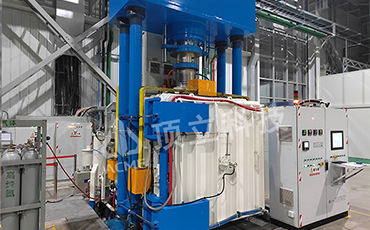

II. Vacuum Graphitization Furnace: The“Precise Transformation Chamber”for Carbon-Carbon Composites

The vacuum graphitization furnace for carbon-carbon composites is not merely a high-temperature vessel, but aprecise system integrating thermal engineering, vacuum technology, and intelligent control. Every design element is engineered to achieve“precise transformation”and“performance assurance”:

Core Components and Technical Highlights:

High-Vacuum System: Utilizes efficient sealing structures and multi-stage vacuum pumping to create apure graphitization environment, rapidly expelling impurity gases and clearing obstacles for carbon structural transformation.

High-Temperature Heating System: Employs high-temperature-resistant, oxidation-resistant heating elements paired with multi-zone temperature control design. This enables precise regulation of heating rates and holding temperatures to meet the graphitization requirements of diverse materials.

Anti-Contamination Structure: The furnace chamber interior utilizes high-purity, corrosion-resistant materials to prevent reactions with materials at high temperatures while minimizing impurity adhesion, ensuring product purity.

Stress Control Design: Equipped with flexible insulation and support structures within the furnace to mitigate thermal stress caused by temperature gradients, ensuring material dimensional stability during graphitization.

Core Technical Features:

Fully Controllable Process: Programmed control throughout heating, holding, and cooling phases. Process curves adjustable based on material properties to guarantee product consistency.

Wide Adaptability: Processes carbon-carbon composite blanks of varying sizes and shapes—whether plates, components, or irregularly shaped parts—achieving uniform graphitization.

Safety and Reliability: Equipped with comprehensive temperature and vacuum monitoring systems plus anomaly alarms, ensuring real-time control of furnace conditions and mitigating safety risks in high-temperature vacuum environments.

III. Cross-Industry Applications: Deployment of Carbon-Carbon Composites in Critical Scenarios

Carbon-carbon composites processed in vacuum graphitization furnaces showcase exceptional performance across multiple high-end sectors:

1. Aerospace: Reliable Support in Extreme Environments

In critical components like rocket engine nozzles, spacecraft thermal protection systems, and aircraft brake discs, carbon-carbon composites fully leverage their lightweight and high-temperature resistance. The stable structure imparted by graphitization enables them to withstand extreme heat and gas flow impacts, maintaining consistent performance through drastic temperature fluctuations to safeguard aerospace equipment operations.

2. High-End Manufacturing: The“Performance Carrier”for Precise Equipment

In thermal field components of semiconductor manufacturing equipment and high-temperature structural parts of industrial furnaces, the high thermal conductivity and heat resistance of carbon-carbon composites are indispensable. Graphitized materials enable uniform heat transfer while withstanding prolonged high-temperature conditions, reducing equipment wear, enhancing operational precise, and extending service life.

3. New Energy Sector: The“Core Components”for Efficient Operation

In critical structural components for photovoltaic and wind power equipment, as well as moderator materials for nuclear reactors, carbon-carbon composites play a vital role due to their corrosion resistance, radiation resistance, and stability. Graphitization treatment ensures long-term performance stability under complex operating conditions, safeguarding the efficient and safe operation of new energy equipment.

4. Transportation Equipment: The“Performance Upgrade Solution”for Lightweighting

In structural components of high-speed trains and high-end racing cars, carbon-carbon composites offer distinct advantages in lightweighting and high strength. Graphitized materials reduce equipment weight while maintaining structural integrity and safety, enabling transportation equipment to achieve lightweighting and performance upgrades.

IV. Future Outlook: Technology Upgrades Enable Broader Applications

As high-end manufacturing demands increasingly stringent material performance, the vacuum graphitization furnace process for carbon-carbon composites is evolving toward greater intelligence, efficiency, and environmental sustainability:

SmartPrecise: Integrating IoT and intelligent algorithms enables real-time optimization and automatic adjustment of process parameters, further enhancing product consistency and production efficiency;

Adapting to Diverse Demands: Optimizing furnace structures and process systems to meet requirements for composite modified carbon-carbon materials and irregularprecise components, expanding application boundaries;

Green and Energy-Efficient Development: Developing low-energy heating technologies and high-efficiency insulation materials to reduce equipment operational energy consumption, while optimizing exhaust gas treatment methods to minimize environmental impact;

Performance Breakthroughs: Through furnace design enhancements and process innovations, we advance the graphitization level and performance of carbon-carbon composites to meet the demands of more extreme and demanding applications.

Conclusion: Empowering Advanced Material Upgrades by Transformation

From carbon-basedbody to high-end composites, vacuum graphitization furnaces for carbon-carbon composites achieve transformative material performance through precise process control. Critical components in aerospace, high-end manufacturing, and other sectors rely on the silent empowerment of this“transformation equipment.”Looking ahead, as technology continues to advance, the vacuum graphitization process for carbon-carbon composites will continually push performance boundaries. This will enable carbon-carbon composites to play a pivotal role in more critical sectors, injecting robust momentum into the high-quality development of advanced manufacturing.

The Latest News

Vacuum Graphitization Furnace Process for Carbon-Carbon Composites: Forging the “Graphite Core” of High-End Materials

Aluminum Nitride Ceramic Vacuum Hot Press Furnace Process: Unlocking the “Thermal Conductivity Core” for High-End Manufacturing

Silicon Carbide Vacuum Debinding Sintering Furnace Process: Forging the “Dense Core” of High-End Ceramics