Aluminum Nitride Ceramic Vacuum Hot Press Furnace Process: Unlocking the “Thermal Conductivity Core” for High-End Manufacturing

In cutting-edge fields such as 5G communications, power electronics, and aerospace, the thermal conductivity, insulation properties, and structural stability of materials are emerging as critical bottlenecks for technological breakthroughs. When traditional ceramic materials struggle to balance high-temperature resistance with efficient thermal conductivity, aluminum nitride (AlN) ceramics emerge as the “ideal choice” for high-end device packaging and extreme-environment structural components. This is due to its core advantages: thermal conductivity 5-8 times that of alumina ceramics, superior insulation properties, and a thermal expansion coefficient matching silicon. The core equipment for transforming aluminum nitride powder into high-performance ceramic products—the aluminum nitride ceramic vacuum hot-press furnace—is now forging the “thermal conductivity backbone” for modern technology through precise process design. This advancement propels high-end materials from laboratory research toward industrial-scale applications.

I. Vacuum Hot Pressing Process for Aluminum Nitride: “Dense Forming” Under High Pressure and Temperature

If conventional ceramic sintering is a slow transformation toward “natural porcelain formation,” the vacuum hot pressing process for aluminum nitride represents “precise forging” through the synergistic action of high pressure and high temperature. Using high-purity aluminum nitride powder as raw material, this process operates within a sealed vacuum furnace. By simultaneously applying thousands of atmospheres of pressure and temperatures between 1800-2000°C, the powder particles undergo plastic flow and diffusion sintering under “thermal activation” and “pressure-driven” conditions. This ultimately forms an aluminum nitride ceramic green body with a density approaching its theoretical maximum. This process eliminates the need for traditional sintering binders, preventing impurity introduction at the source and maximizing material performance.

Core Process Advantages:

Ultra-High Density: Vacuum environment suppresses pore formation, while hot pressing synergistically achieves ceramic density exceeding 99.9%, significantly enhancing thermal conductivity efficiency;

Balanced Performance: Delivers high thermal conductivity while maintaining excellent electrical insulation (breakdown voltage >15kV/mm) and mechanical strength (flexural strength >350MPa);

Precise Dimensions: Pressure forming and precise temperature control minimize sintering shrinkage deformation, enabling dimensional tolerances within ±0.1mm without extensive post-processing;

Controllable Purity: Vacuum atmosphere effectively prevents oxidation of aluminum nitride. Sintering additives like yttrium oxide (Y₂O₃) allow precise regulation of thermal conductivity and sintering activity.

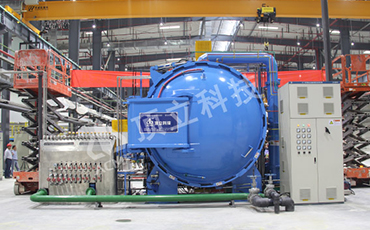

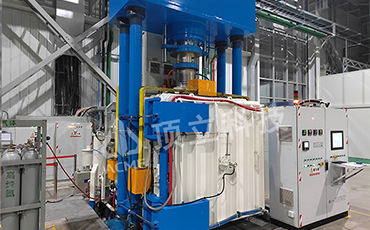

II. Vacuum Hot Press Furnace: The “Precise Forging Chamber” for Aluminum Nitride Ceramics

The vacuum hot press furnace for aluminum nitride ceramics is not merely a “high-temperature, high-pressure vessel.” It is a complex system integrating thermodynamics, materials science, and precise control technology. Each core component directly determines the final product's performance:

Core Components and Technical Highlights:

VacuumAirtight System: Utilizes a metal-sealed structure with a multi-stage vacuum pump assembly to achieve ultra-high vacuum levels of 10⁻³ to 10⁻⁵ Pa. This completely isolates oxygen, preventing the oxidation of aluminum nitride into aluminum oxide impurities at high temperatures and safeguarding thermal conductivity.

High-Pressure Containment Structure: The furnace chamber utilizes high-strength graphite or tungsten-molybdenum alloy materials, paired with a hydraulically driven pressurization system. This delivers stable, balanced pressure ranging from 10 to 50 MPa, ensuring thorough particle bonding and eliminating internal voids.

Precise Temperature Control System: Utilizes multi-zone infrared heating with PID intelligent temperature regulation, achieving temperature uniformity with an error margin ≤±5°C. Enables programmable control throughout heating, holding, and cooling phases to meet the temperature requirements of different sintering stages for aluminum nitride.

Anti-Contamination Design:

Inner chamber components in contact with materials are coated with high-purity graphite or boron nitride to prevent metal impurity contamination, ensuring the purity and performance stability of ceramic products.

Technological Breakthroughs:

Ultra-Large-Scale Forming: Next-generation equipment enables one-piece forming of large-size aluminum nitride ceramic blanks measuring Φ500mm × 100mm, meeting high-power device packaging demands;

Rapid Sintering Technology: Optimized heating rates and pressure curves reduce sintering cycles from conventional 10–12 hours to 4–6 hours, boosting production efficiency;

Intelligent Monitoring: Integrated real-time monitoring and data traceability systems for furnace chamber temperature, pressure, and vacuum levels enable precise replication of process parameters and quality control.

III. Cross-Industry Applications: Real-World Scenarios Showcasing the “Hardcore Capabilities” of Aluminum Nitride Ceramics

High-performance aluminum nitride ceramics, fabricated using vacuum hot-press furnaces, are achieving critical applications across multiple high-end sectors through their combined advantages of “high thermal conductivity + electrical insulation + high-temperature resistance”:

1. Power Electronics Packaging: Cooling and Lightening the Load for Chips

In new energy vehicle inverters, 5G base station power amplifiers, industrial frequency converters, and similar equipment, the thermal dissipation efficiency of power chips directly determines operational stability and lifespan. With a thermal conductivity of 200–320 W/(m·K), aluminum nitride ceramic substrates have emerged as the ideal replacement for traditional alumina ceramics and BeO ceramics.

Application Case: A new energy vehicle manufacturer adopted vacuum hot-pressed aluminum nitride ceramic substrates for IGBT module packaging. This reduced chip operating temperature by 25°C, increased power density by 40%, and shrunk inverter volume by 30%.

Core Advantage: Its thermal expansion coefficient (4.5×10⁻⁶/℃) closely matches that of silicon chips (3.5×10⁻⁶/℃), effectively mitigating thermal stress and preventing substrate cracking.

2. Aerospace: A “ProtectiveScreen” for Extreme Environments

In scenarios such as rocket engine combustion chambers, satellite attitude control engine nozzles, and hypersonic vehicle thermal protection systems, materials must withstand extreme temperatures, high pressures, and rapid thermal cycling. Aluminum nitride ceramics,manufactured via vacuum hot pressing, can endure temperatures exceeding 1800°C while exhibiting outstanding thermal shock resistance.

Technical Highlights: Aluminum nitride ceramics exhibit excellent bonding properties with metal components, enabling the formation of composite structures through brazing processes. Within the high-temperature gas channels of aerospace engines, they fulfill dual functions of thermal insulation and load-bearing, extending service life by more than threefold.

3. Semiconductor Manufacturing: The “Key Components” of High-End Equipment

In semiconductor wafer manufacturing processes such as etching and thin-film deposition, a large number of high-temperature resistant, corrosion-resistant, and contamination-free structural components and carriers are required. Aluminum nitride ceramics, with their strong chemical stability and absence of metallic impurity leaching, have become the core material for wafer carriers and reaction chamber linings.

Application Value: Vacuum hot-pressed AlN ceramic carriers achieve surface roughness Ra ≤ 0.1μm, enabling high-precise wafer support and uniform heat transfer. This reduces temperature fluctuations during processing and enhances chip yield.

IV. Future Outlook: The “Upgrading Path” for Aluminum Nitride Vacuum Hot Press Technology

As high-end manufacturing demands increasingly stringent material performance, the vacuum hot-pressing process for aluminum nitride ceramics is evolving toward greater efficiency, environmental sustainability, and intelligence:

Cost Reduction Breakthrough: By optimizing sintering additive formulations and enhancing equipment capacity utilization, unit costs for aluminum nitride ceramics have been reduced by over 30%, accelerating large-scale adoption in civilian applications.

Functional Composite Integration: Combining aluminum nitride with reinforcing phases like carbon fibers and silicon carbide particles via vacuum hot-pressing to produce ceramic matrix composites with both high thermal conductivity and toughness, expanding applications in high-speed trains, drones, and other sectors;

Green Upgrades: Developed low-energy heating technologies and recyclable vacuum systems to reduce equipment operational energy consumption. Simultaneously optimized sintering aid compositions to minimize environmental pollutant emissions;

Micro-scale Adaptation: Designed compact vacuum hot-pressing equipment tailored for micro-electro-mechanical systems (MEMS) and micro-sensors, enabling precise forming of micron-level aluminum nitride ceramic components.

The Latest News

Vacuum Graphitization Furnace Process for Carbon-Carbon Composites: Forging the “Graphite Core” of High-End Materials

Aluminum Nitride Ceramic Vacuum Hot Press Furnace Process: Unlocking the “Thermal Conductivity Core” for High-End Manufacturing

Silicon Carbide Vacuum Debinding Sintering Furnace Process: Forging the “Dense Core” of High-End Ceramics