Silicon Carbide Vacuum Debinding Sintering Furnace Process: Forging the “Dense Core” of High-End Ceramics

In advanced manufacturing, new energy, aerospace, and other fields, silicon carbide ceramics have emerged as a key material to replace traditional metals and ordinary ceramics due to their exceptional properties of high strength, high-temperature resistance, and corrosion resistance. To transform the mixed green body of silicon carbide powder and binder into a structurally dense, stable-performance finished product, thesilicon carbide vacuum debinding sintering furnace plays the pivotal role of the “ultimate refiner.” By precisely controlling the entire debinding and sintering process, it removes impurities and strengthens the structure, fully unlocking the potential of silicon carbide ceramics. This provides robust and reliable material support for high-end equipment.

I. Vacuum Debinding and Sintering Process for Silicon Carbide: The Transformation from “Green Body” to “Hard Ceramic”

If Green Body’s forming constitutes the “shaping” stage of silicon carbide ceramics, then the vacuum debinding and sintering process is the critical step that gives it its “strength and structure.” This process comprises two core stages: First is the debinding process, where gradual heating under vacuum gently decomposes and expels the binding agents used in blank formation, avoiding deformation and contamination associated with traditional debinding methods. Subsequently, the sintering stage occurs at elevated temperatures within a vacuum atmosphere. Here, silicon carbide particles undergo diffusion and fusion, ultimately forming structurally dense ceramic products with superior performance. This entire process occurs free from external impurities, achieving a seamless transformation from loose powder bodies into high-strength ceramics.

Core Process Advantages:

Purity Guaranteed: The vacuum environment isolates oxygen and external impurities, preventing high-temperature oxidation of silicon carbide while eliminating residual decomposition products from binders to ensure product purity.

Dense Structure: Continuous debinding and sintering processes reduce porosity in green bodies, enhancing material density and mechanical strength for superior wear and impact resistance.

Excellent Dimensional Stability: Gradual heating and uniform temperature control effectively release internal stresses in the green body, preventing cracking and deformation duringdebinding and sintering.

Wide Adaptability: Capable of processing silicon carbide green bodies of various shapes and sizes, achieving uniformdebinding and sintering for both complex-structured irregular parts and large-area plates.

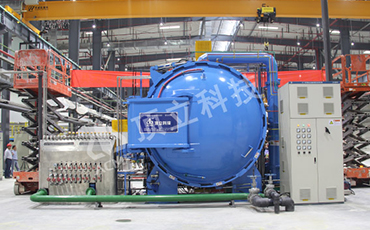

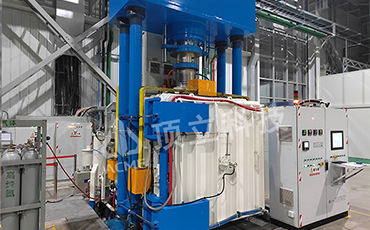

II. VacuumDebinding and Sintering Furnace: The “Precision Refining Chamber” for Silicon Carbide Ceramics

The silicon carbide vacuumdebinding and sintering furnace is a precision apparatus integrating thermal engineering, vacuum technology, and intelligent control. Every component is designed around “precise control” and “performance assurance”:

Core Components and Technical Highlights:

Vacuum Assurance System: Utilizes high-efficiency sealing and vacuum extraction to create a pristinedebinding and sintering environment. This prevents material oxidation while rapidly expelling binder decomposition products, clearing obstacles for subsequent sintering.

Gradient Temperature Control System: Achieves precise control over heating rates through multi-zone heating and intelligent regulation. It maintains gentle temperature control duringdebinding and stable heat retention during sintering, adapting to the process requirements of different formulation green bodies.

Anti-Contamination Structure: The furnace chamber lining utilizes special high-temperature resistant and corrosion-resistant materials to prevent reactions with silicon carbide at elevated temperatures while minimizing impurity adhesion, ensuring product cleanliness.

Stress Relief Design: Equipped with adjustable support and insulation structures within the furnace, it reduces thermal stress caused by temperature gradients, helping green bodies maintain dimensional stability throughout thedebinding and sintering process.

Core Technical Features:

Integrated Process:Debinding and sintering are completed within the same furnace chamber, eliminating the need for intermediate blank transfer. This reduces external environmental impact on products and enhances production efficiency.

Flexible Adaptability: Process parameters can be adjusted based on the composition and dimensions of silicon carbide blanks. Compatible with various binder systems to meet diverse product requirements.

Safety and Reliability: Equipped with comprehensive temperature and pressure monitoring systems along with anomaly alarms, enabling real-time control of furnace conditions to mitigate safety risks under high-temperature and high-pressure environments.

III. Cross-Industry Applications: Real-World Deployment of Silicon Carbide Ceramics' “Hardcore Scenarios”

Refined through vacuumdebinding and sintering furnaces, silicon carbide ceramics leverage their exceptional properties to achieve widespread adoption across multiple high-end sectors:

1. Mechanical Manufacturing: The “Long-Lasting Choice” for Wear-Resistant Components

In high-wear parts like pump impellers, valve cores, and mechanical seals, silicon carbide ceramics fully leverage their exceptional hardness and abrasion resistance. The vacuumdebinding sintering process ensures a dense ceramic structure that resists wear and spalling, significantly extending component lifespan and reducing equipment maintenance costs.

2. New Energy Sector: The “Safety Barrier” for Stable Operation

In electric vehicle motor housings and core components of charging stations, silicon carbide ceramics combine insulation with high-temperature resistance, ensuring stable equipment operation under intense workloads. For outdoor components in photovoltaic and wind power equipment, their corrosion and aging resistance withstand harsh environmental erosion.

3. Aerospace: Reliable Support in Extreme Environments

In high-temperature components of aircraft engines and thermal protection structures of spacecraft, silicon carbide ceramics withstand extreme heat and gas flow impacts. The dense structure achieved through vacuumdebinding and sintering prevents cracking during drastic temperature fluctuations, ensuring safe flight for aerospace equipment.

4. Electronics and Information Technology: The “Adaptive Carrier” for Precision Components

In structural components of semiconductor manufacturing equipment and electronic packaging housings, silicon carbide ceramics' low thermal expansion coefficient and excellent thermal stability minimize the impact of temperature fluctuations on precision devices, ensuring the operational accuracy and reliability of electronic equipment.

IV. Future Outlook: Technology Upgrades Enable Broader Applications

As high-end manufacturing demands increasingly stringent material performance, silicon carbide vacuumdebinding sintering furnace technology is evolving toward greater intelligence, efficiency, and environmental sustainability:

Intelligent Control Upgrades: Integrating IoT and big data technologies enables real-time optimization and automatic adjustment of process parameters, enhancing product consistency and production efficiency.

Adapting to Diverse Needs: Optimizing furnace structures and process curves to accommodate composite silicon carbide materials and irregular precision components, expanding application boundaries.

Green Energy-Saving Development: Developing low-energy heating technologies and high-efficiency insulation materials to reduce operational energy consumption, while optimizing debinding exhaust treatment to minimize environmental impact;

Continuous Performance Enhancement: Through furnace design improvements and process optimization, further increasing the density and mechanical properties of silicon carbide ceramics to meet more demanding application scenarios.

Conclusion: Forging the Foundation of High-End Manufacturing Through “Firing”

From powder blanks to high-performance ceramics, the silicon carbide vacuum debinding and sintering furnace achieves a qualitative leap in material properties through precise process control. Behind every silicon carbide ceramic component used in various high-end equipment lies the silent empowerment of this “refining apparatus.” Looking ahead, as technology continues to advance, the vacuumdebinding and sintering process for silicon carbide will continually push performance boundaries. This will enable silicon carbide ceramics to play a greater role in critical fields, injecting robust momentum into the development of high-end manufacturing.

The Latest News

Vacuum Graphitization Furnace Process for Carbon-Carbon Composites: Forging the “Graphite Core” of High-End Materials

Aluminum Nitride Ceramic Vacuum Hot Press Furnace Process: Unlocking the “Thermal Conductivity Core” for High-End Manufacturing

Silicon Carbide Vacuum Debinding Sintering Furnace Process: Forging the “Dense Core” of High-End Ceramics