Deepening Research in Lithium Battery Recycling Technology Beijing University of Technology, ACME, and Others Publish Paper in Nature

On October 22, 2025, a research paper titled“A circular economy approach for the global lithium-ion battery supply chain” was jointly published in the internationally renowned journal Nature by Beijing University of Technology, Guangzhou Institute of Energy Conversion, Chinese Academy of Sciences, Jinggangshan University, Beijing Normal University,ACME, and other institutions.

The core innovation of this study lies in pioneering the development of the“Lithium Battery Life Cycle Computable General Equilibrium (LCCGE) Model.” It systematically reveals the complex trade-offs between economic efficiency and regional equity during the decarbonization of the global lithium battery supply chain, providing comprehensive decision-making support for global governance that transcends single perspectives. This lays the foundation for establishing equitable international governance frameworks and promoting circular economy technology transfer. The findings not only offer a scientific blueprint for deep decarbonization of the complex global lithium battery supply chain but also contribute new momentum to fundamental research in reshaping the global green lithium battery industry chain.

With the rapid development of the new energy vehicle industry, power batteries are gradually entering their end-of-life phase. Improper disposal of retired lithium batteries poses severe environmental hazards. Simultaneously, these batteries contain valuable metals such as lithium, cobalt, and nickel, making their efficient recycling strategically important for safeguarding national resource security. The 15th Five-Year Plan explicitly states that the lithium battery industry must transition from“scale-driven leadership” to“quality-driven leadership.” A core task involves establishing a standardized, safe, and efficient recycling system covering the entire battery lifecycle, thereby achieving resource circularity and high-quality industrial development.

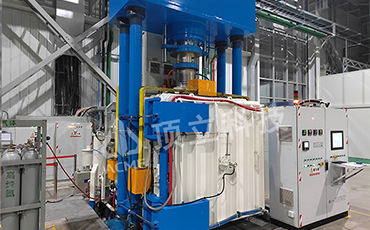

In recent years, leveraging its extensive expertise in thermal engineering equipment,ACME has successfully applied advanced thermal processing technologies to the field of lithium battery resource recycling. Through deep industry-academia-research collaborations with institutions such as Beijing University of Technology, the Institute of Process Engineering at the Chinese Academy of Sciences, and the Guangzhou Institute of Energy Conversion at the Chinese Academy of Sciences, the company has provided engineering validation and equipment support for scientific research, achieving multiple significant breakthroughs. The company's integrated pre-treatment system forhigh-quality utilization of end-of-life power batteries encompasses multiple unitsincluding pre-discharge, crushing, drying/pyrolysis, sorting and separation, and exhaust gas treatment, enabling efficient and high-quality recovery of black powder, copper, aluminum, and other materials.

Additionally, the company has introduced multi-element calcination technology and equipment for ternary black powder derived from pretreated waste power batteries. This encompasses a full range of calcination processes including“carbon reduction calcination, hydrogen reduction calcination, natural gas reduction calcination, and sulfidation calcination,” laying the foundation for wet-process lithium extraction. The related technology and equipment have been successfully applied by leading enterprises in new energy battery recycling.

Beyond lithium battery recycling, the company's series of intelligent environmental thermal processing equipment has been widely adopted in recycling applications including carbon fiber fan blades, solar photovoltaic panels, waste enameled copper wire, and discarded circuit boards.

From developing critical equipment and providing comprehensive solutions to engaging in cutting-edge academic research, ACME will continue deepening industry-academia-research collaboration.

This commitment aims to advance the innovative application of thermal processing technologies across more critical sectors of the circular economy, contributing to the development of a green, low-carbon, and sustainable future.