Technical Analysis and Practical Application of Vacuum High-Pressure Gas Quenching Furnaces

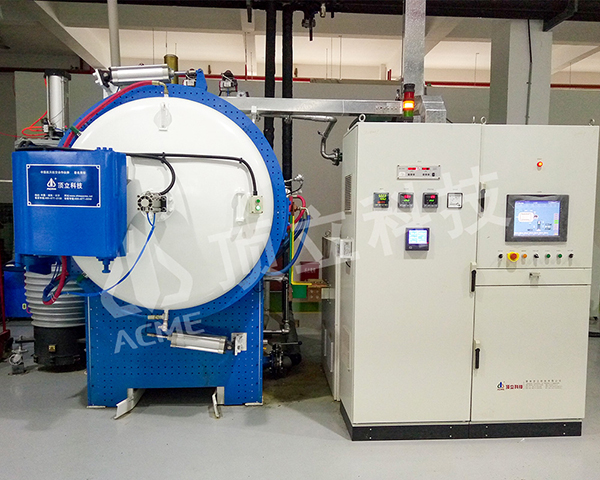

In high-end manufacturing, the enhancement of material properties often hinges on “the final decisive step” of heat treatment processes. As a core piece of equipment in modern heat treatment, theVacuum High-Pressure Gas Quenching Furnaceis redefining the performance boundaries of precision components through its unique technological advantages. This article will delve into its technical core and application value.

I. Technical Principle: Synergistic Effect of Vacuum and High-Pressure Gas

The core design concept of the vacuum high-pressure gas quenching furnace is “non-oxidizing quenching + controlled rapid cooling.” Its operational working procedure comprises three stages:

1. Vacuum Pretreatment

The furnace chamber is pumped to high vacuum (typically ≤10⁻³ Pa), thoroughly eliminating oxygen and water vapor to prevent material from oxidation and decarburization at high temperatures. This stage is particularly suitable for heat treatment of reactive metals like titanium alloys and high-temperature alloys.

2. High-Temperature Homogenization

Heating to target temperatures (up to 1350°C) under vacuum or inert gas condition ensures the uniformity of internal microstructure. Advanced temperature control systems maintain fluctuations within ±3°C.

3. High-Pressure Gas Quenching

Utilizes high-pressure nitrogen or helium (2-20 bar) as the cooling medium. Turbulent flow generated through high-speed nozzles achieves rapid cooling of the workpiece. Compared to traditional oil quenching, gas quenching achieves cooling rates exceeding 100°C/s. Cooling gradients can be precisely controlled by adjusting pressure and gas flow velocity.

II. Technical Advantages: Breaking Through Traditional Quenching Bottlenecks

1. Oxidation-Free Surface and Environmental Sustainability

The vacuum environment eliminates oxide layer formation during quenching, maintaining a surface roughness of Ra <0.4 μm without the need for subsequent acid cleaning or sandblasting. Moreover, the process eliminates the use of quenching oil, avoiding issues related to oil smoke pollution and waste liquid disposal.

2. Minimized Quenching Distortion

The uniform cooling characteristics of high-pressure gas significantly reduce uneven thermal stress distribution. For example, in tool steels, flatness deviation after gas quenching can be reduced by 50%–70% compared to oil quenching, substantially lowering post-processing costs for precision components.

3. Broad Material Adaptability

The process accommodates a wide range of materials, from aerospace-grade titanium alloys (e.g., Ti-6Al-4V) and nickel-based superalloys (e.g., Inconel 718) to tool steels (e.g., H13) and stainless steels. By adjusting gas pressure and type (e.g., helium provides 3–4 times higher cooling rates than nitrogen), ideal martensitic transformation can be achieved.

III. Industrial Applications: The "Invisible Driving Force" in High-End Manufacturing

• Aero-engine Blades: Utilizing ultra-high-pressure helium quenching (15-20 bar) to increase the endurance strength of single-crystal superalloys by 20%, while preventing grain boundary embrittlement.

• Precision Injection Molds: After vacuum gas quenching, H13 steel achieves a hardness uniformity of HRC 58±1, extending mold service life by over 30%.

• Medical Device Components: 316L stainless steel artificial joints subjected to oxidation-free quenching exhibit enhanced corrosion resistance, meeting the requirements of ASTM F138 standards.

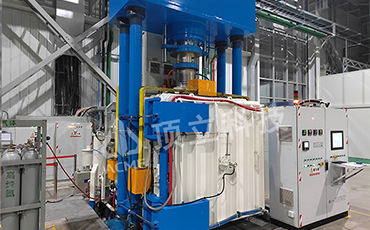

ACME's vacuum high-pressure gas quenching furnaces stand out in the global market with their leading technical parameters, reliable operational performance, and customized solution capabilities. Adopting advanced vacuum system design and high-efficiency gas circulation technology, ACME's equipment ensures exceptional uniformity in temperature control and cooling rates, effectively meeting the stringent heat treatment requirements of high-end precision components. With a strong focus on energy efficiency and environmental protection, ACME's furnaces reduce energy consumption while minimizing environmental impact, aligning with the sustainable development trends of modern manufacturing. Whether for aerospace, precision machinery, or advanced mold industries, ACME provides comprehensive technical support and after-sales service, helping customers optimize production processes and enhance product competitiveness.