Analysis of the research status and development trend of China's powder metallurgy thermal equipment

Definition of powder metallurgy

Powder metallurgy refers to the process technology of preparing metal powder or using metal powder (or a mixture of metal powder and non-metal powder) as raw materials to manufacture metal materials, composite materials and various types of products.

Powder metallurgy process: Definition of powder metallurgy equipment: powder metallurgy thermal equipment is used to realize the process of calcination, reduction, carbonization, sintering, sintering, post-processing and other auxiliary equipment.

Present situation of domestic powder metallurgy equipment industry

Carbide production, according to authorities in China have nearly 50% of total worldwide production of rare earth materials occupy more than 90% Synthetic diamond powder 80%, iron powder has been more than a third of above, all this shows that China is the worlds largest producer of powder metallurgy, the development of the domestic powder metallurgy industry, verifying the thermal equipment of powder metallurgy industry is rapidly developing.

In the new pattern of technology globalization, the domestic powder metallurgy thermal equipment has been greatly improved, the overall technology can meet the basic requirements of the domestic powder metallurgy industry, is moving toward the international advanced level, but there is still a large gap compared with the developed countries.

1. The comprehensive technology gap is large: the application of intelligent control technology is backward, and the informatization degree of equipment manufacturing is low.

2. The industrialization level gap is large: foreign countries mostly use intelligent robot rapid automatic detection and other advanced means, domestic mostly manual operation, testing equipment is backward, equipment industrialization level is low.

3. There is a big gap in innovation ability: overseas is mainly reflected in the achievements of key generic technology, while most of the domestic use of simple process improvement, or even imitation.

The development trend of powder metallurgy thermal equipment in China

Upsizing of equipment capacity

Large-scale equipment production capacity is the most direct way to achieve efficient production and maximum benefit. At present, the manufacturing of the largest and most advanced powder metallurgy thermal equipment in the world is almost concentrated in the western developed countries.

Aiming at the problem of large-scale equipment production capacity, Dingli Technology has developed a 10,000-ton belt reduction equipment. The equipment has a high degree of automation, the width of the steel belt reaches 1.5m, the maximum annual output can reach 12000t, and it has a significant energy saving effectThe energy consumption and performance of the products are more than those of the steel belt furnace imported from the United States. The overall technology has reached the international advanced level. It has applied for 4 patents and has been applied in Wuhan Iron and Steel Group and other units

Intelligent control means

In the context of modern mass production, the traditional powder metallurgy equipment has been unable to adapt to improve the quality of powder metallurgy products, the key depends on whether the powder metallurgy thermal equipment has advanced intelligent control means, specifically, that is, the precise control process digital and reliable operation.

In the course of developing modern powder metallurgy thermal equipment, Dingli Technology takes intelligent control means as its development direction: configuring industrial computer to realize intelligent process control;The gas system adopts intelligent centralized flexible control to improve the stability of the atmosphere in the furnace and ensure the overall consistency of the products.IPC technology is used to realize on-line operation management such as temperature regulation and atmosphere control to improve the intelligent level of equipment.The statistical process control technology (SPC) was used to establish the mathematical model of the process parameters, and the parameters were accurately monitored by sensors and microcomputers based on the statistical parameter control.

Features of automatic intelligent 18-tube furnace developed by Dingli Technology

1. Automatic operation: with automatic loading, pushing, discharging and reversing mechanism, the product quality is stable.

2.High efficiency and energy saving: the use of 18 pipes up and down the double boat production at the same time, improve the production efficiency, multi-area independent temperature control of the new thermal field structure design, to achieve the maximum energy utilization.

3. Intelligent control: through fault self-diagnosis intelligent decision-making flexible control, unattended;Enhance customer benefits through remote and online services, quick response.

Green development direction

Top state science and technology to overcome the large powder metallurgy equipment all warm control technology, through the reasonable design temperature compensation, heater shape and distribution, as well as the thermal insulation layer modular design, and USES the area 17 separate independent temperature control, successfully solves the large equipment temperature control, temperature uniformity deviation big technical problems, such as equipment heating zone volume is 31.25 m3, The uniformity of furnace temperature is up to ±5℃.

Integration of device functions

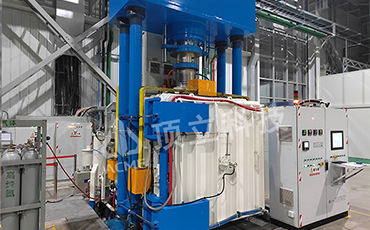

The new multi-function pressure sintering furnace developed by Ding Li Technology combines the degreasing vacuum sintering and gas quenching heat treatment processes of products in one furnace body, which saves the degreasing furnace for customers through multi-function integrationFor the equipment investment of vacuum sintering furnace and gas quenching heat treatment furnace, customers only need to invest this set of new equipment to realize all the above procedures, so that customers can reduce a lot of equipment investment costs and achieve high performance and quality of products.