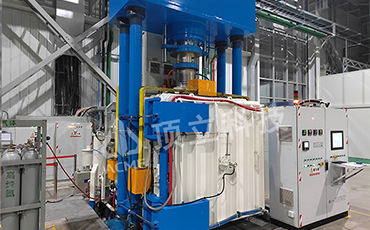

vacuum carburizing gas quenching furnace

Today we will introduce thevacuum carburizing gas quenching furnacedeveloped byACME. This equipment is mainly used for vacuum carburizing or carbonitriding heat treatment processes of key parts in the fields of aerospace, weapons, etc.

The technical advantage of this equipment is that it can not only complete the vacuum carburizing heat treatment process, but also complete the vacuum carbonitriding heat treatment process, and complete the gas quenching process at the same time. The vacuum carburizing process solves the problem of internal oxidation of the workpiece that cannot be solved by multi-purpose furnace atmosphere carburizing. In addition to the bright surface of the vacuum carburized workpiece, the carburizing quality of the workpiece is significantly better than that of atmosphere carburizing, and the fatigue resistance and wear resistance are greatly improved.

The vacuum carburizing equipment has higher flexibility in use and is equipped with a dedicated process system, without the need to worry about controlling the size of the carbon type. The equipment adopts a double-chamber structure, one is carburizing and the other is a quenching chamber. After the parts complete vacuum carburizing or carbonitriding in the carburizing chamber, they are quickly transferred to the quenching chamber to complete the high-pressure gas quenching process. The maximum gas quenching pressure in the quenching chamber is 20 bar. The heat treatment quality of the workpieces treated by the vacuum carburizing furnace fully meets the requirements of carburizing and carbonitriding of high-end parts, especially the indicators such as carbon concentration on the workpiece surface, depth of the carburized layer, and quenching hardness fully meet and exceed the requirements of navigation marks.