classification

- Heat Treatment & Brazing Thermal Equipment

- Carbon & Ceramic Thermal Equipment

- Powder Metallurgy Thermal Processing Equipment

- Organic Solid Waste Thermal Pyrolysis Equipment

- High purity carbon material and Coated graphite component

- Atomization Powder Manufacturing Equipment

- 3D Print New Material & Parts

Contact Us

+86-151 7315 3690( Jessie Mobile)

ACME Xingsha Industrial Park, East Liangtang Rd. , Changsha City, Hunan

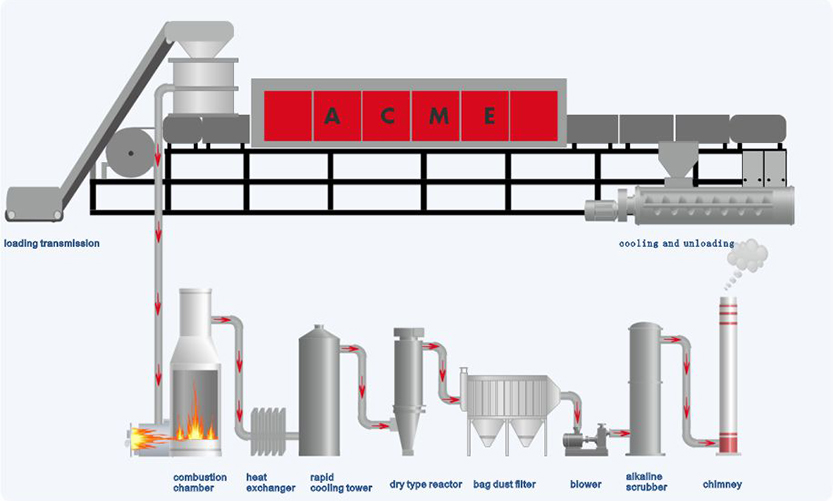

Disposal battery thermal pyrolysis recycling equipment(Belt type)

ACME has developed a demonstration line for the full-process high-quality utilization of waste power batteries, covering an integrated solution from “individual battery cells to black powder, copper, and aluminum.” During the recycling process of waste batteries, the pretreatment stage can be divided into three processes: drying, drying + pyrolysis, and pyrolysis alone. After pretreatment, reduction treatment can enhance the recovery rate of metals such as lithium, nickel, and cobalt in the wet leaching process.

The integrated lithium battery recycling equipment employs a combination of low-temperature drying and medium-temperature pyrolysis, enabling more effective removal of organic substances such as electrolyte and binder.

- Technical Features

- Related optional configuration

Product Description

ACME has developed a demonstration line for the full-process high-quality utilization of waste power batteries, covering an integrated solution from “individual battery cells to black powder, copper, and aluminum.” During the recycling process of waste batteries, the pretreatment stage can be divided into three processes: drying, drying + pyrolysis, and pyrolysis alone. After pretreatment, reduction treatment can enhance the recovery rate of metals such as lithium, nickel, and cobalt in the wet leaching process.

The integrated lithium battery recycling equipment employs a combination of low-temperature drying and medium-temperature pyrolysis, enabling more effective removal of organic substances such as electrolyte and binder.

Technical Features

The key technologies of "shredding and crushing + low-temperature electrolyte drying + organic pyrolysis + separation + multi-high value metal roasting", such as multi-stage composite treatment, precise control of temperature field and flow field, continuous automatic operation of equipment and collaborative treatment of multi-pollutants in reaction process, have been developed. A combined process system with the core of "low temperature drying of electrolyte, pyrolysis of organic matter and roasting of high value metal" is established, which can realize the process purpose of "waste power battery → complete separation of black powder, copper and aluminum, and priority extraction of lithium by roasting of black powder".

Process:

The pyrolysis process uses the thermal instability of organics to heat material under non-oxygen atmosphere to volatilize or decompose organics such as electrolyte and diaphragm paper under high temperature.

Efficient medium temperature thermolysis of organic matter:

Through development of high efficient medium temperature pyrolysis technology of organic matter and anaerobic sealed environment pyrolysis system, the temperature of pyrolysis system is raised to 400-600℃, and PVDF decomposes; In addition, the macromolecular chain will generate HF removal reaction when heated, and the carbon chain will break, forming fluorobenzene and other fluoroorganics. After pyrolysis, the pole piece will break, so as to weaken the binding force between the electrode material and the fluid collector. Combined with simple crushing and sieving, a purer cathode material can be obtained to realize the mutual dissociation of electrode materials.

Efficient medium temperature thermolysis of organic matter:

By developing High value metal high temperature reduction technology and heat treatment system , hydrogen, carbon or natural gas are used as reducing agents to raise the temperature of the reduction system to 600

Technical parameter

Model | SBF-1500/200-14 |

Raw material type | Lithium battery crushing material ,Aluminum granules, battery powder material , battery wet electrode powder, phosphate iron lithium waste cathode sheet |

Annual output | Customized in accordance with treatment output |

Organic remove rate | ≥99.5% |

Oxygen content | <1% |

Type of heating | Electrical/Gas heating |

Pyrolysis temperature | 150-700℃(Controllable) |

Temperature uniformity of section area inside furnace | ±5℃ |

Floor space | Approx. 600㎡(Annual output:10,000ton) |

Emission compliance | The exhaust is compliance with the project local highest emission standard |

Features and advantages

Equipment with high automation

High removal rate of organic

High quality of high-value products

European and American emission standards compliance