One article to understand the vacuum high pressure gas quenching furnace

1. What is vacuum high pressure gas quenching?

Vacuum high pressure gas quenching refers to tool steel, high-speed steel and alloy steel that are easily hardenable materials. After being loaded into the vacuum furnace to reach the vacuum degree specified by the process, it is heated to the critical temperature Ac3 or Ac1 or above, and kept warm according to the process requirements. For a period of time, then quickly fill in high-pressure inert gas (He, Ar) or non-reactive gas N2 or other mixed gas, the room reaches the specified pressure (10bar, 20bar, 40bar), and at the same time turn on the high-power fan to drive the heat-resistant fan. The hot workpiece is blown at high speed. After the hot air flow passes through the special heat exchanger for heat exchange and cooling, the cold air flow purifies the workpiece again, and finally a heat treatment process of martensitic quenching structure is obtained.

Schematic diagram of the quenching temperature range of steel

2. Application of vacuum high pressure gas quenching furnace Tool Steel, Die Steel, High Speed Steel, Ultra High Strength Steel

3.Application of vacuum high pressure gas quenching furnace

300M steel, gas quenching under 10bar N2:

It can be seen from the figure that the hardness of the Ф60 round bar has reached the oil quenching effect (generally about 53HRC), and the core is a lath martensite structure with good hardenability. The Ф80 round bar does not meet the above requirements. This shows that the degree of hardening of the workpiece is affected by the hardening ability of the equipment.

8Cr4Mo4V steel, gas quenching under 0.2MPa N2:

Test results of 8Cr4Mo4V steel roller bearing D10 XX /01 under gas/oil quenching process

Quenching requirements: hardness 60 ~ 64HRC; organization M2 ~ M4; deformation (cylindrical, flatness) should be controlled between 0.20mm.

When the hardness and microstructure meet the standards, the unqualified rates of the roundness and flatness of the gas quenched workpiece are 20% and 10%, respectively, while that of the oil quenched workpiece are 70% and 70%. It can be seen that gas quenching can significantly reduce the deformation of the workpiece.

4. Advantages of vacuum high pressure gas quenching

The surface quality of the workpiece is good, no oxidation, no carbon increase, and no alloying element depletion.

The quenching uniformity is good, and the deformation of the workpiece is small.

The cooling speed is controllable. The cooling speed is controlled by changing the inflation pressure and airflow direction, and the fan speed (frequency conversion). Ideally, it can be close to isothermal quenching.

The whole process has no pollution and no waste gas emission, and the gas quenched workpiece does not need secondary cleaning, which is efficient, energy-saving and environmentally friendly.

5. The main influencing factors of the quenching effect of high pressure gas quenching furnace

| Types of quenching effectsInfluencing factors | Influencing factors |

| cooling rate | Cooling gas pressure, air volume, air speed during quenching |

| Workpiece hardening depth | Select the type of gas during quenching, the size of the heat exchange area and the heat exchange rate of the heat exchanger, the internal structure, and the arrangement of the workpiece |

| Hardness uniformity of workpiece after quenching | Gas quenching pressure, air volume, air speed, heat transfer speed |

6. The main factors affecting the cooling rate of the workpiece

| Quenching gas pressure | Generally, the pressure increases, the cooling rate increases, and the pressure increases to 40bar, which is close to the cooling rate in static oil. |

| Quenching gas flow | Increasing the airflow is beneficial to increase the cooling rate and increase the heat exchange capacity. |

| Quenching gas flow rate | The faster the quenching gas flow rate, the greater the number of heat exchanges and the faster the speed. |

| Quenching gas type | Different types of quenching gas have different cooling rates for workpieces H2>He>N2>Ar |

7.The main factors affecting the quenching depth of the workpiece

| Gas quenched AISH10 tool steel | |

| Gas quenching pressure | Workpiece quenching depth |

| 6bar nitrogen | 110mm |

| 10bar nitrogen | 130mm |

| 20bar nitrogen | 170mm |

◆The gas quenching pressure not only affects the cooling rate of the workpiece, but also affects its hardenability, so it must be selected carefully.

8、ACME Vacuum Air Quenching Furnace

Vertical bottom charging vacuum air quenching furnace

Technical characteristics of ACME vertical bottom charging vacuum air quenching furnace:

The furnace body is vertical, single-chamber, bottom-loading, especially suitable for long rod-shaped workpieces.

The bottom furnace door lift transmission mechanism adopts ball screw, which moves in a straight line, not easy to get stuck, and has a protective cover to prevent dust pollution.

The direction-changing cooling technology can be used for both longitudinal spray cooling and 360° circumferential cooling.

The lifting bracket is equipped with an automatic balance correction mechanism, which automatically eliminates the cumulative error of the lifting system. The lifting is stable and there is no vibration.

Horizontal vacuum high pressure gas quenching furnace

Technical characteristics of ACME horizontal vacuum high pressure gas quenching furnace:

The furnace liner is modularly designed, and the furnace temperature uniformity and cooling uniformity are all good.

Depending on the different cooling speed requirements of the parts, a single heat exchanger and a two-stage or even multi-stage heat exchanger furnace cooling structure can be selected.

For the actual processing parts, the rear suction gas quenching circulation system or the front suction gas quenching circulation system can be selected.

Unique two-stage heat exchanger, the heat exchange area is doubled compared to the conventional one.

Technical Features of ACME Gas Quenching Furnace

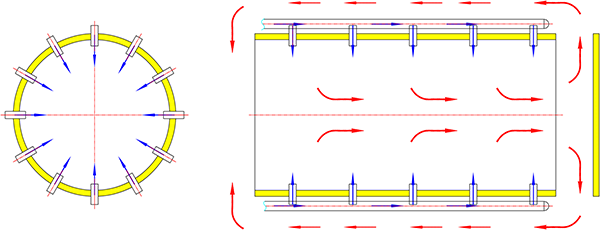

◆Circular thermal field structure: The nozzle type can arrange multiple nozzles around the thermal chamber at 360°, so that the airflow is blown to the workpiece in all directions to achieve uniform cooling, and the system has a simple structure and is the most widely used.

◆Square thermal field structure: The high-speed cold air is shot to the workpiece through the nozzle of the airflow distribution plate, and the hot air is discharged through the distribution plate. After heat exchange through the heat exchanger, the return air circulates along the pipeline and blows toward the workpiece to achieve isothermal cooling. Finished process.

◆Triple cooling effect (ACME patented technology): Unique rear return air flow technology, triple cooling function, front and rear dual heat exchanger configuration, better effect.