ACME breaks through ton-level mass production technology for high-purity AlON powder, promoting advanced optical ceramic research and application

Since its discovery, aluminum nitride (AlON) has garnered significant attention due to its exceptional properties. Its primary performance advantages are highlighted in the following areas:

1. Outstanding optical properties

AlON ceramics exhibit excellent transmittance across the visible to mid-infrared wavelength range, with theoretical transmittance comparable to that of single-crystal sapphire. This makes it an ideal material for optical components such as infrared windows and laser protective covers.

2. Robust mechanical properties

AlON ceramics combine high hardness and high bending strength with excellent high-temperature mechanical properties, maintaining high strength even at elevated temperatures. They are suitable for applications such as high-temperature observation windows and transparent armor components.

3. Chemical and thermal stability

AlON ceramics are resistant to acid-alkali corrosion and oxidation, capable of withstanding corrosion from most acids, alkalis, and organic substances. They also exhibit excellent thermal shock resistance, making them widely applicable in various harsh working environments.

Overall, AlON, as a transparent ceramic, has performance comparable to sapphire. It not only has excellent optical properties but also high strength, high hardness, and resistance to high temperatures, rain erosion, and sand erosion. However, its production cost is lower than that of sapphire, and it is more suitable than sapphire for manufacturing complex-shaped components. Therefore, AlON ceramics have become one of the most promising infrared window materials.

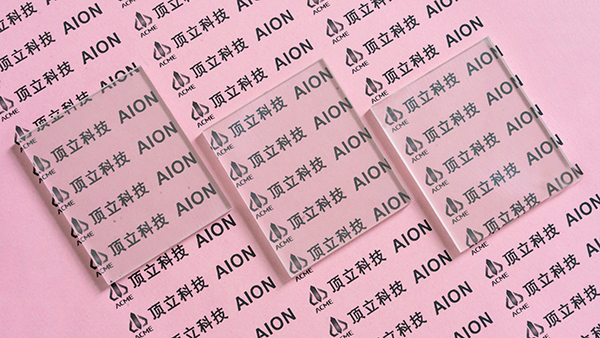

AlON transparent ceramic

To prepare AlON transparent ceramics with excellent comprehensive performance, it is necessary to first obtain high-purity, ultra-fine AlON powder, as its performance directly affects the performance of the final ceramic. Specifically, insufficient powder purity can lead to many problems, such as making the powder prone to hydrolysis and difficult to store, as well as reducing the performance of the prepared ceramic. Additionally, the sintering activity of AlON powder is closely related to its particle size. Generally, the smaller the particle size, the larger the specific surface area, resulting in higher sintering activity and facilitating the production of dense, high-performance ceramics.

AlON powder

Currently, there are several methods for preparing AlON powder, with the two most commonly used methods being as follows.

01. High-temperature solid-phase synthesis method

The high-temperature solid-phase synthesis method involves synthesizing AlON powder using high-purity Al₂O₃ and AlN in a nitrogen atmosphere. For this method, due to the hygroscopic nature of AlN powder, moisture absorption and contact with water must be avoided during mixing, resulting in a complex raw material mixing process, extended production time, and high labor costs, making it unsuitable for large-scale production. Additionally, the reaction products often contain residual Al₂O₃ and/or AlN, which are difficult to separate and remove, causing significant damage to the performance of the prepared AlON transparent ceramics.

Al2O3(s)+AlN(s)→AlON(s)

02.Carbothermal reduction nitridation method

The method of mixing carbon powder as a reducing agent with high-purity alumina and sintering it in a high-temperature nitrogen atmosphere to obtain AlON powder is called thecarbothermal reduction nitridation method (CRN method). The following reactions occur during the reaction:

Al2O3(s)+C(s)+N2(g)→AlON(s)+CO(g)

During thecarbothermal reduction nitridation reaction, most of the AlN is generated in situ on the surface of Al₂O₃ particles. Compared with high-temperature solid-phase reactions, this process is more complete, produces smaller particle sizes, and typically leaves only easily removable C in the reaction products.

Therefore, compared to other methods, the CRN method is simpler, has a shorter production cycle, and is more cost-effective, making it suitable for large-scale industrial production. However, during the CRN reaction process, especially in batch synthesis, the formation of the AlON phase is highly susceptible to temperature and atmosphere conditions, and the reactivity of raw material mixtures prepared using different mixing methods varies significantly. Therefore, by reasonably controlling the raw materials, mixing methods, and synthesis processes in the CRN method for synthesizing AlON powder, it is possible to obtain AlON powder with stable phase composition and consistent components, thereby facilitating the preparation of AlON transparent ceramics with superior comprehensive performance.

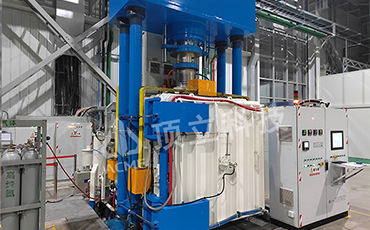

High-temperature powder synthesis equipment

Given the high production difficulty and stringent quality requirements associated with AlON powder,ACMEleverages its nearly 20 years of expertise in thermal engineering equipment R&D. By deeply integrating equipment and process technologies, the company has overcome the technical challenges through years of R&D efforts, successfully breaking through the bottleneck in the large-scale, stable synthesis of high-purity, ultra-fine AlON powder viacarbothermal reduction nitridation. The company now possesses the production capacity to manufacture ton-scale high-purity, ultra-fine AlON powder annually, with each batch achieving a purity of≥99.9% and a controllable particle size distribution (D50: 1–5μm), meeting the diverse requirements of various application scenarios. This breakthrough in key technology and the establishment of industrialization capabilities will facilitate the research and development and industrialization of high-performance AlON transparent ceramics.