classification

- Heat Treatment & Brazing Thermal Equipment

- Carbon & Ceramic Thermal Equipment

- Powder Metallurgy Thermal Processing Equipment

- Organic Solid Waste Thermal Pyrolysis Equipment

- High purity carbon material and Coated graphite component

- Atomization Powder Manufacturing Equipment

- 3D Print New Material & Parts

Contact Us

+86-151 7315 3690( Jessie Mobile)

ACME Xingsha Industrial Park, East Liangtang Rd. , Changsha City, Hunan

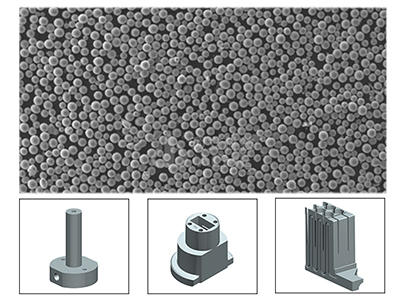

Spherical Aluminum Alloy Powder

ACME uses PREP method, which is using metal or alloy as the consumable electrode, and under the centrifugal force to produce spherical metal powder. This method avoid the slug and contact with refractory material, eliminate the non-metal impurities, and produce high purity spherical powder.

- Technical Features

- Related optional configuration

Spherical Aluminum Alloy Powder

| Grade | Chemical Composition | Product Standard | Particle Size Distribution | ||

| Main Element | Impurity Element | National Standard | USA Standard | ||

AlSi10Mg (ZL104) | Si:10-11 Mg:0.4-0.45 Fe:0.14-0.55 Cu:<0.05 Mn:<0.01-0.45 Al:Bal | Ni:<0.01-0.05 Zn:<0.01-0.1 Pb:<0.01-0.05 Sn:<0.01-0.05 Ti:<0.01-0.15 O :<0.05 | GB/T 1173-2013 | 15-45μm 15-53μm 53-120μm 53-150μm | |

AlSi12 (ZL102) | Fe:≤0.25 Mn:≤0.1 Si:11.00-13.00 Zn:≤0.2 Al: Bal | Cu:≤0.3 Mg:≤0.1 Pb:≤0.02 Sn:≤0.02 O :<0.05 | GB/T 1173-2013 | 15-45μm 15-53μm 53-120μm 53-150μm | |

AlSi7Mg (ZL101) | Si:6.5-7.5 Mg:0.25-0.45 Al: Bal | O:<0.05 | GB/T 1173-2013 | 15-45μm 15-53μm 53-120μm 53-150μm | |

| 7A04 | Cu:1.4-2.0 Mn:0.2-0.6 Mg:1.8-2.8 Cr:0.1-0.25 Zn:5.0-7.0 Al: Bal | Si:0.5 Fe:0.5 Ti:0.1 O :<0.05 Res Each:0.05 Res Total:0.1 | GB/T 3190-2008 | 15-45μm 15-53μm 53-120μm 53-150μm | |

| 2A12 | Cu:3.8-4.9 Mn:0.3-0.9 Mg:1.2-1.8 Al:Bal | Si:0.5 Fe:0.5 Ni:0.1 Zn:0.3 Ti:0.15 O :<0.05 Res Each:0.05 Res Total:0.1 | GB/T 3190-2008 | 15-45μm 15-53μm 53-120μm 53-150μm | |

| 2A14 | Cu:3.9-4.8 Mn:0.4-1.0 Mg:0.4-0.8 Si:0.6-1.2 Al: Bal | Fe:0.7 Ni:0.1 Zn:0.3 Ti:0.15 O :<0.05 Res Each:0.05 Res Total:0.1 | GB/T 3190-2008 | 15-45μm 15-53μm 53-120μm 53-150μm | |