Vacuum Hot Press: Reshaping the Paradigm of Solid-State Joining in Precise Manufacturing

In today's era where high-end manufacturing pursues ultimate precision and performance, vacuum hot press technology is emerging as an “invisible hero” in core sectors like aerospace and electronic components through its unique solid-state bonding logic. This process, which abandons traditional fusion welding approaches, leverages the synergistic effects of vacuum environments and precise temperature-controlled pressure to achieve atomic-level bonding at the microscopic level. It provides a novel solution for connecting complex structural components and different materials.

The core principle of vacuum hot press involves applying appropriate temperature and pressure to the materials to be welded within an airtight vacuum environment. Under the combined action of heat and pressure, the oxide layer on the material surface is effectively removed. Atoms at the contact interface gain sufficient energy to undergo diffusion and rearrangement, gradually forming a metallurgical bond layer free of pores and impurities. Compared to traditional welding, this solid-state bonding method avoids issues such as composition segregation and coarse grain formation that may occur during melting. It ensures the joint perfectly match the base material, fundamentally guaranteeing the structural stability and service life of the component.

In practical applications, the advantages of vacuum hot press are becoming increasingly obvious. It breaks through the limitations of material types for joining, enabling reliable connections whether it's precise metal-to-metal butt welding or cross-material bonding between metals and ceramics, carbon fiber composites, and other different materials. This provides greater design freedom for lightweight, high-performance engineering in advanced equipment. Simultaneously, the relatively low welding temperature minimally impacts the base material’s inherent properties, maximally preserving the raw material's inherent advantages. This makes it particularly suitable for processing heat-sensitive precision components. Furthermore, since no additional filler material is required, the welding process generates no residual impurities, significantly enhancing the service safety of components under complex operating conditions.

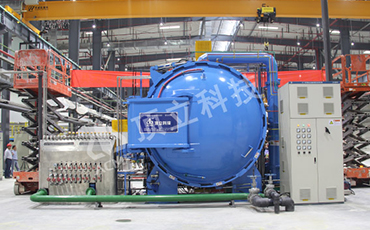

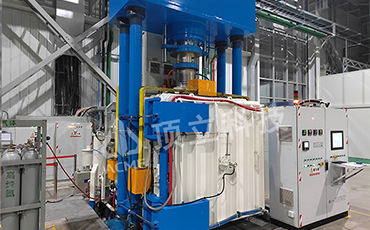

As the core equipment for implementing this technology, the performance ofvacuum hot press furnacesdirectly determines welding quality. Modern vacuum hot press equipment universally features precise temperature-pressure coordination control capabilities. Through multi-zone temperature regulation and dynamic pressure adjustment, it ensures uniform and stable atomic diffusion at the welding interface. Intelligent control systems enable real-time monitoring and traceability of critical parameters like temperature, pressure, and vacuum levels, significantly reducing human operational errors. Concurrently, efficient cooling systems and energy-saving designs enhance production efficiency while further optimizing process economics, laying the foundation for large-scale technological implementation.

However, the widespread adoption of vacuum hot pressing technology still faces certain challenges. It imposes stringent requirements on material surface cleanliness and assembly precision, with even the slightest impurity or deviation potentially compromising the final joint integrity. The initial capital investment in equipment and the technical barriers associated with process debugging also test a company's technological capabilities. Yet, with continuous advancements in materials science and intelligent manufacturing technologies, these challenges are gradually being overcame.

From core components of aircraft engines to precise packaging of high-end electronic devices, vacuum hot press technology is deeply integrating into the manufacturing chain of major national projects with its unique technical advantages. In the future, as equipment costs decrease, processes continue to optimize, and non-destructive testing technologies undergo complementary upgrades, this technology will further expand its application boundaries. It will shine in more civilian high-end manufacturing sectors, injecting sustained momentum into the high-quality development of theprecise manufacturing industry.

The Latest News

Vacuum Graphitization Furnace Process for Carbon-Carbon Composites: Forging the “Graphite Core” of High-End Materials

Aluminum Nitride Ceramic Vacuum Hot Press Furnace Process: Unlocking the “Thermal Conductivity Core” for High-End Manufacturing

Silicon Carbide Vacuum Debinding Sintering Furnace Process: Forging the “Dense Core” of High-End Ceramics